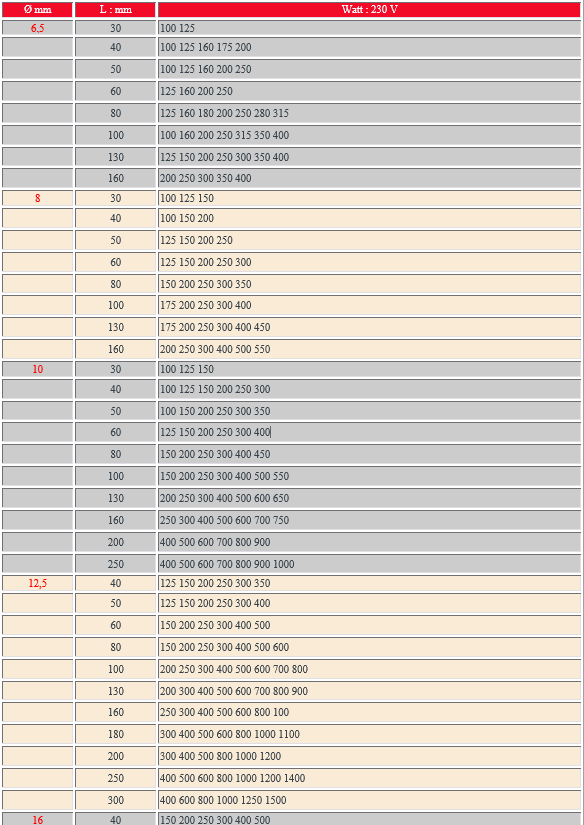

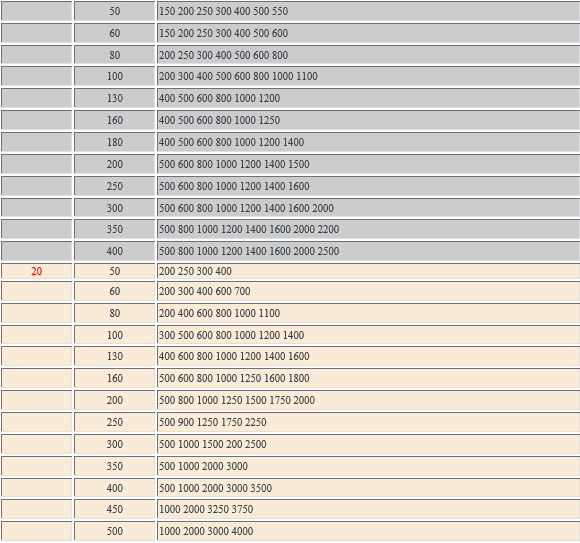

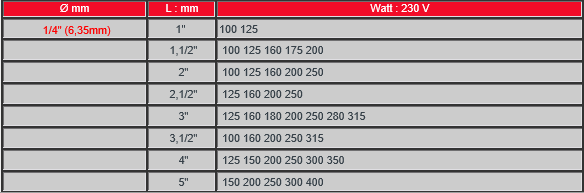

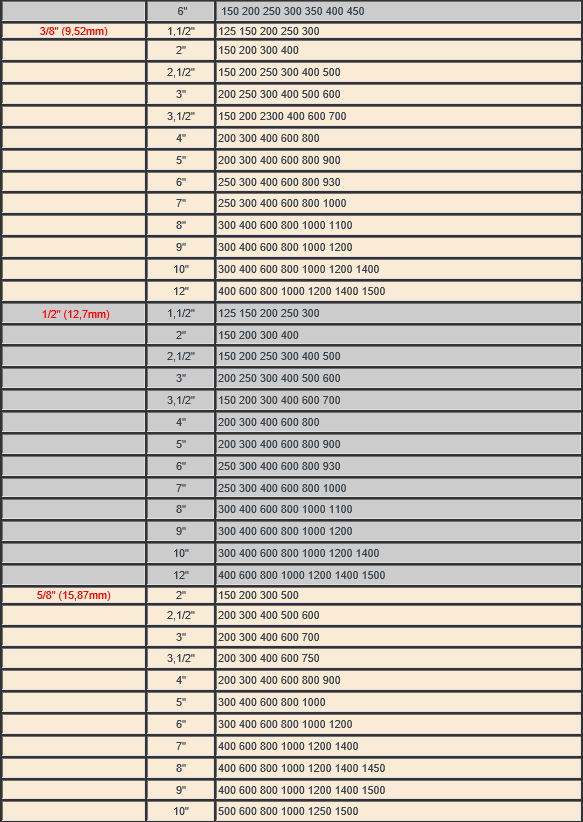

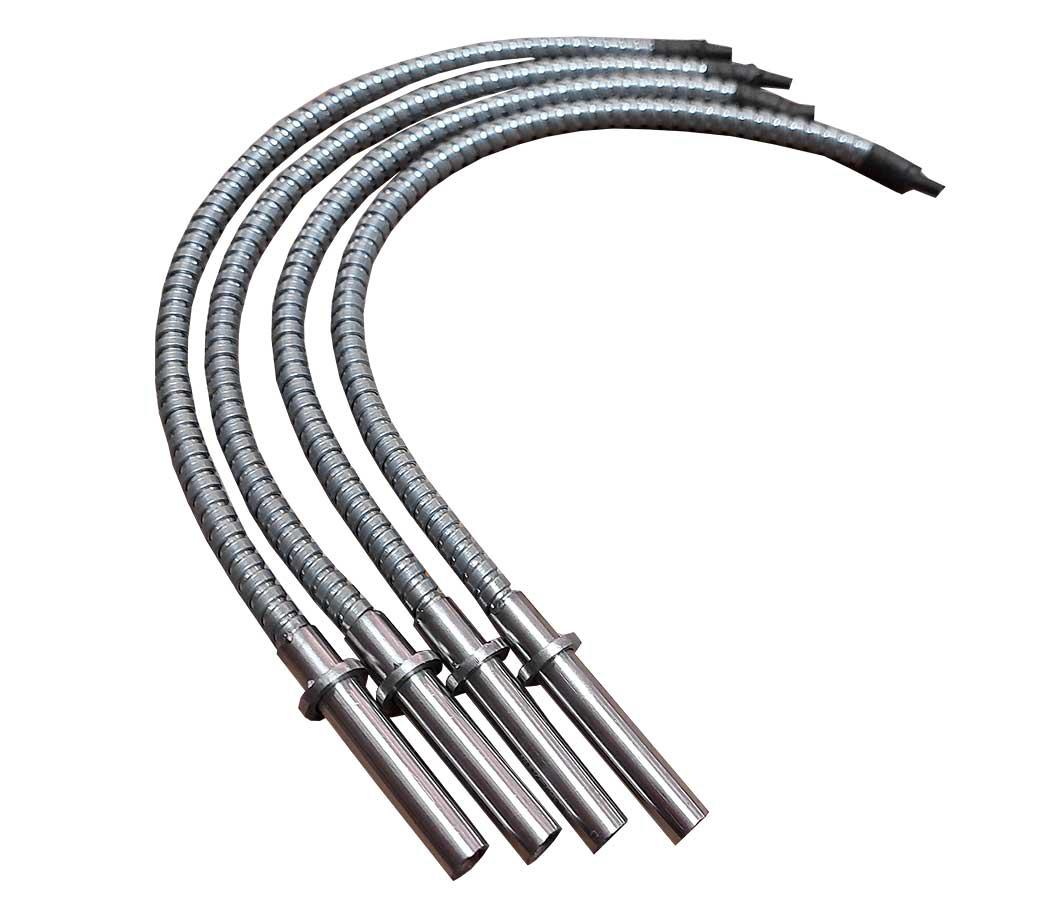

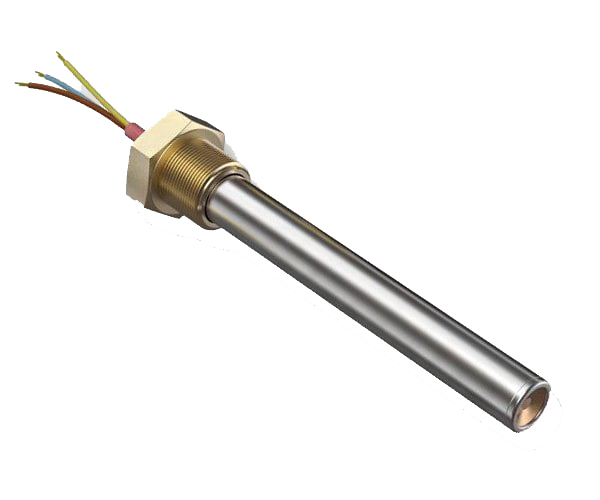

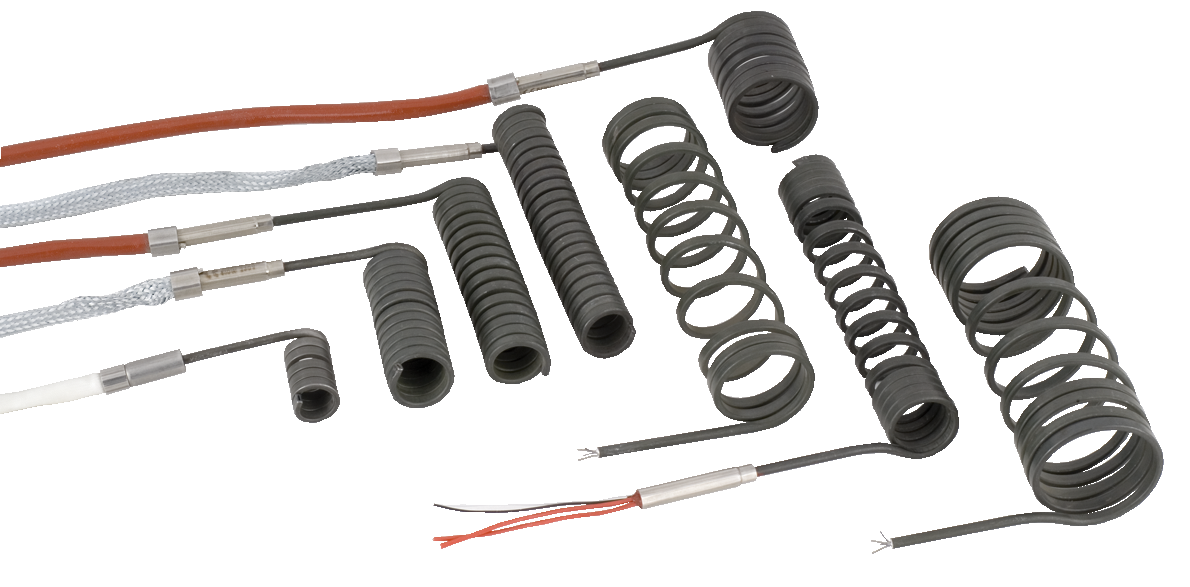

Cartridge Resistance

-High-tech cartridge resistors make it possible to use them in difficult conditions with their high watt density. It is placed in a stainless steel casing, 80/20 chrome-nickel wire is wrapped on a special ceramic, filled with high purity Magnesium Oxide between the casing and the wire and compressed with special molds to achieve high efficiency and perfect heat transfer.

-Cartridge resistors are manufactured according to special orders in desired dimensions and values other than standards.

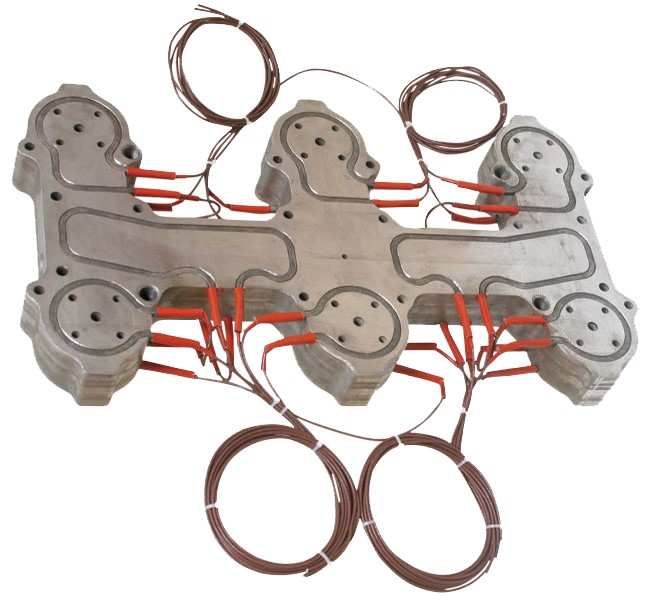

THERMOCOUPLE CARTRIDGE RESISTANCES:

-Our cartridge resistors must be internal FeConst (up to 400ºC) or

Ni-CrNi (after 400ºC) can be produced with thermocouples.

-Thermocouples can be in two different shapes within the resistance.

1-Thermocouple ends are at the bottom, not touching the body.

2-Thermocouple is in the middle of the resistance, with its ends touching the body.

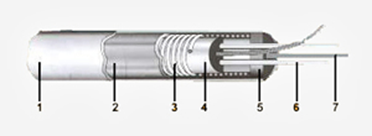

1-CrNi (Stainless outer sheath)

2-High purity compressed MgO

3-80/20 CrNi wire

4-MgO containing ceramic

5-Ceramic tip stone

6-Nickel tip wire

7-Thermocouple wire

- Flexible metal spiral armor to protect the tip exits against all kinds of abrasion, pollution and mechanical damage.

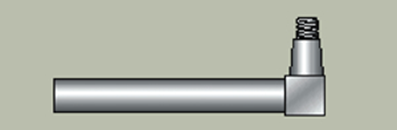

- Protected 90º elbow outlet in areas with space restrictions.

- Protected with 90º cube outlet in areas with space restrictions

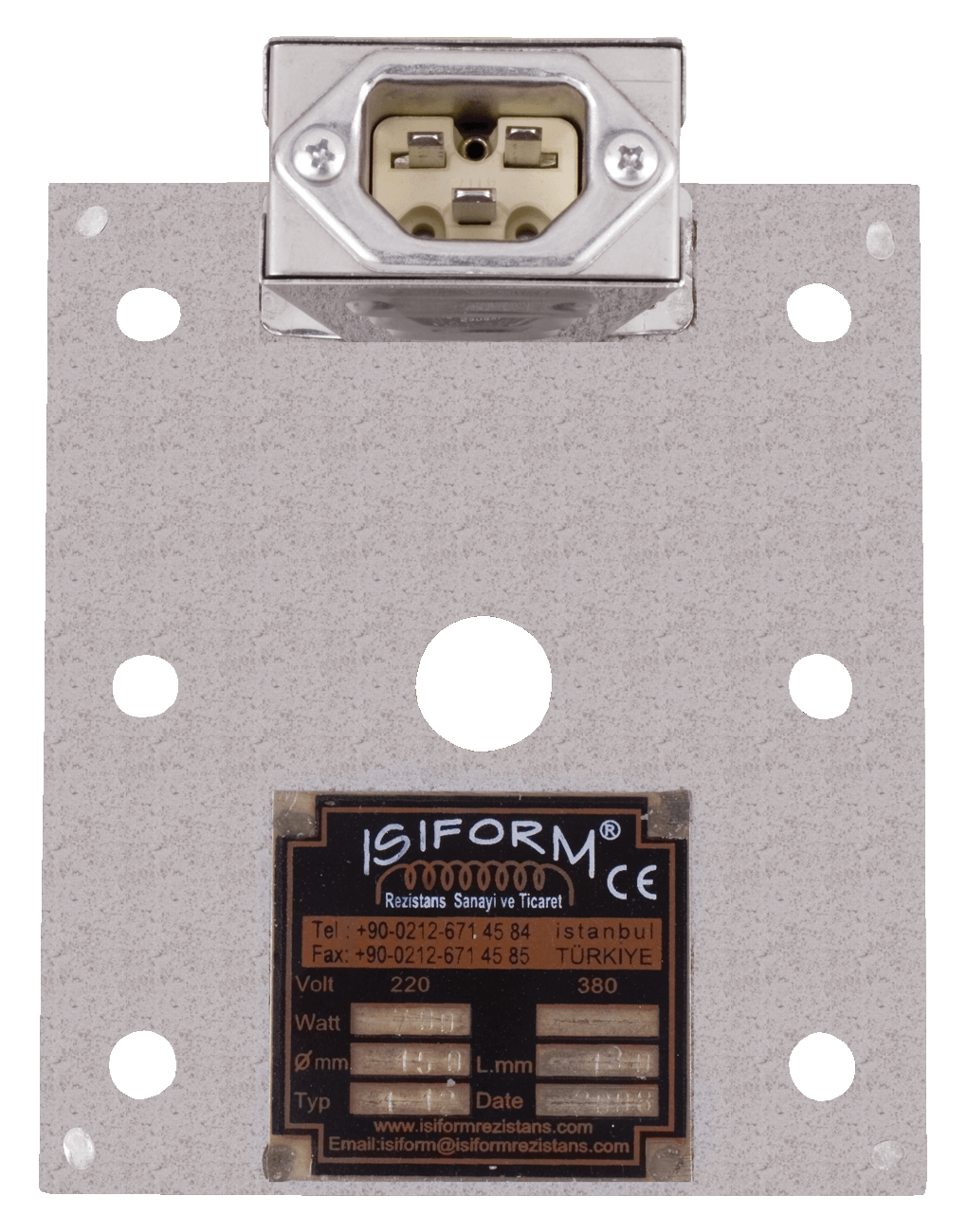

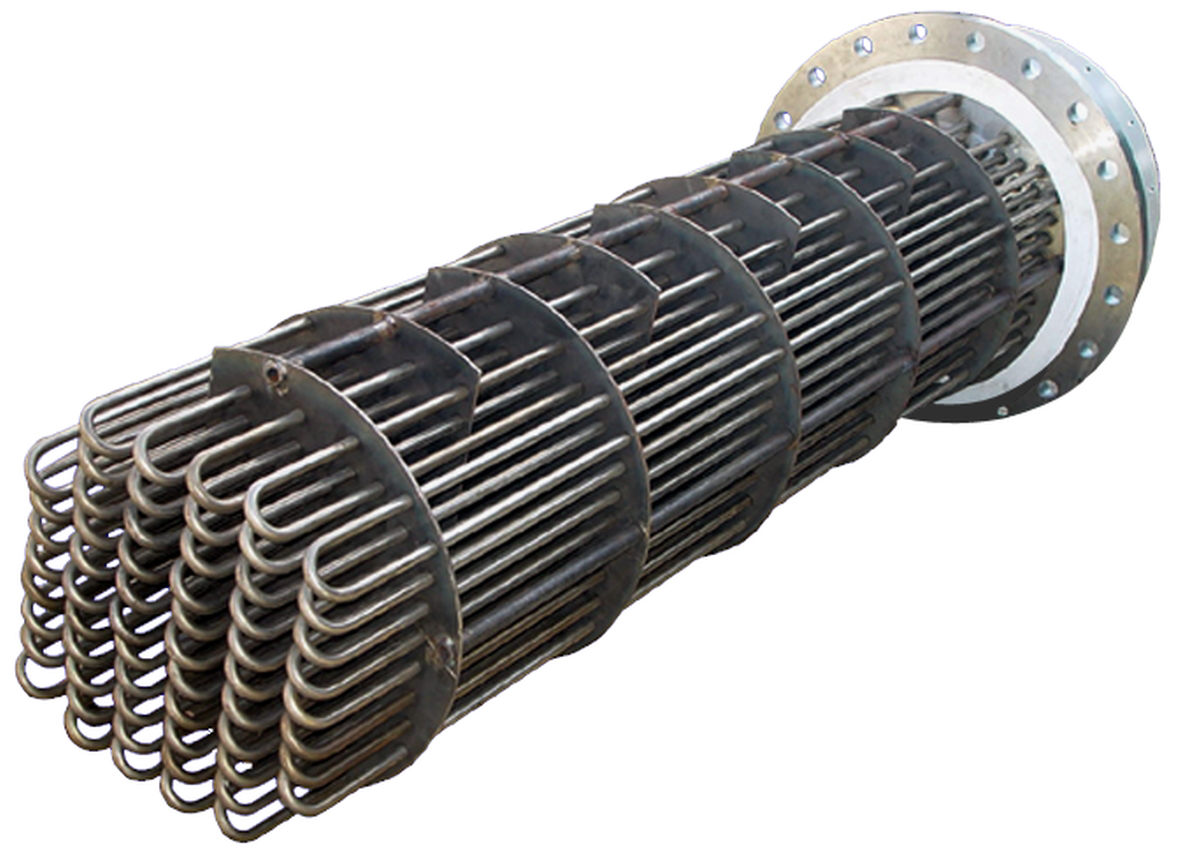

- Suitable for heating liquids with stainless or yellow flange.

- Suitable for heating liquids as stainless or yellow fitting.

Spiral

Cubed

Cantilevered

Flanged

Record