Mica Insulated Resistors

Mica Insulated Resistors Features

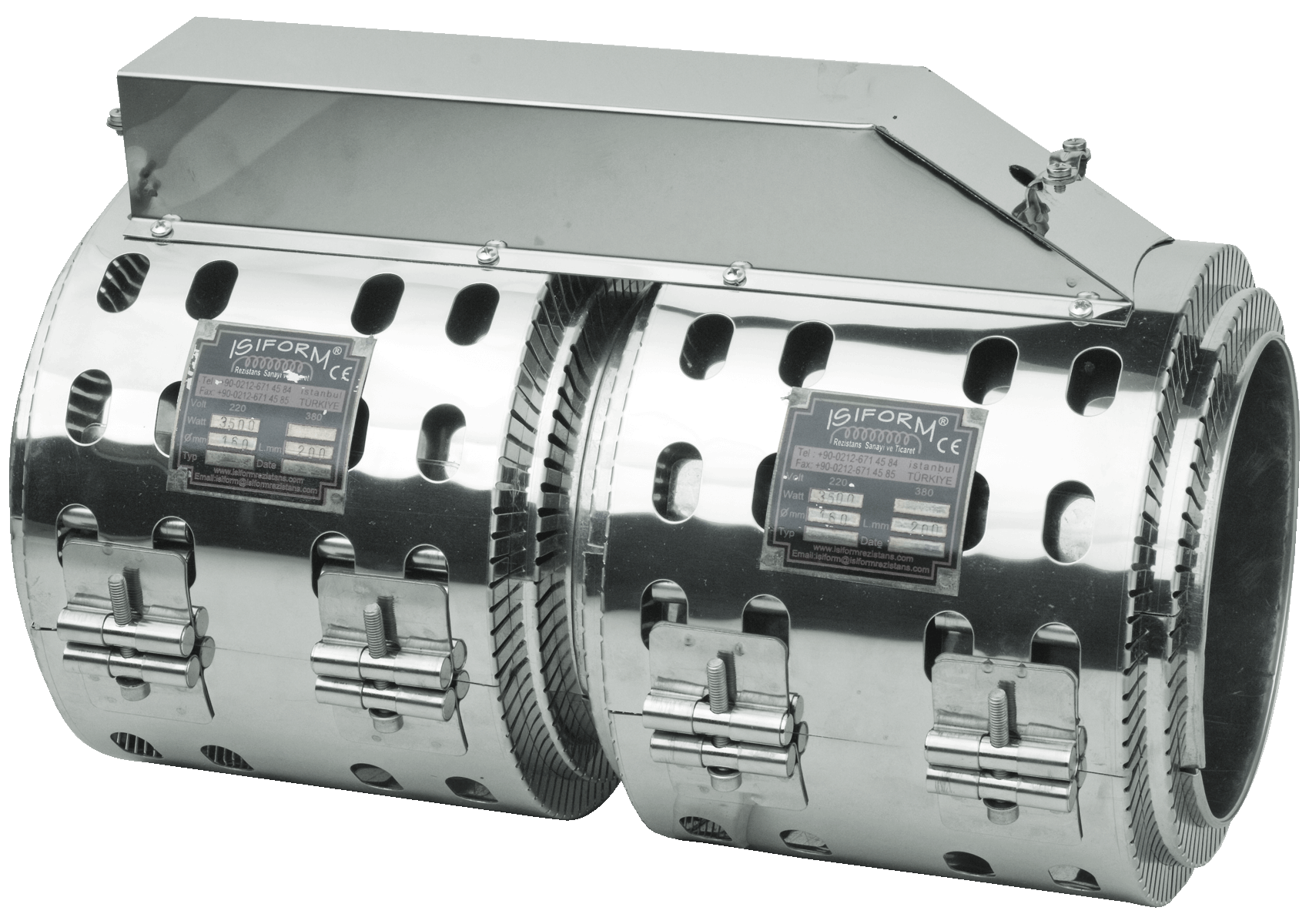

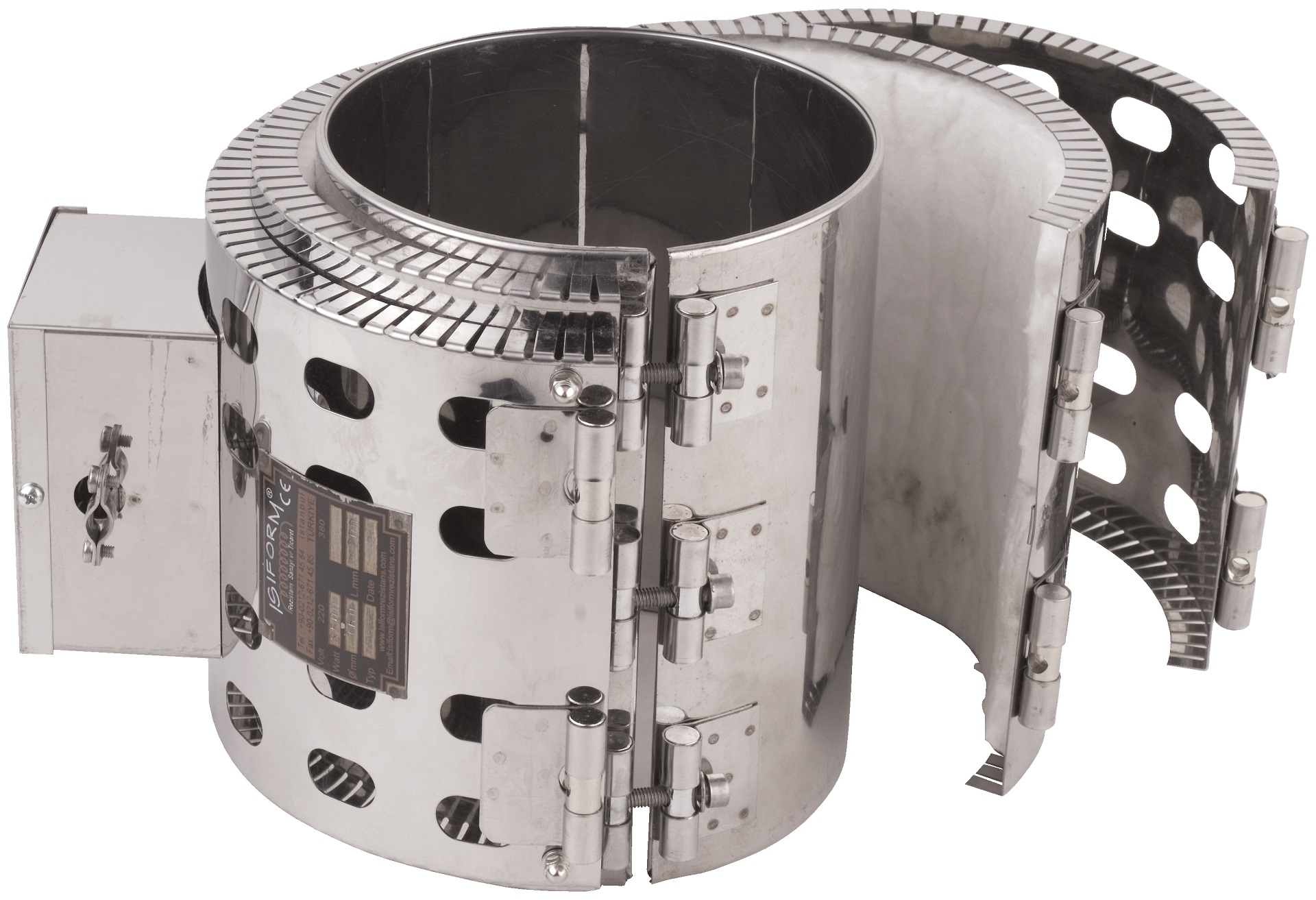

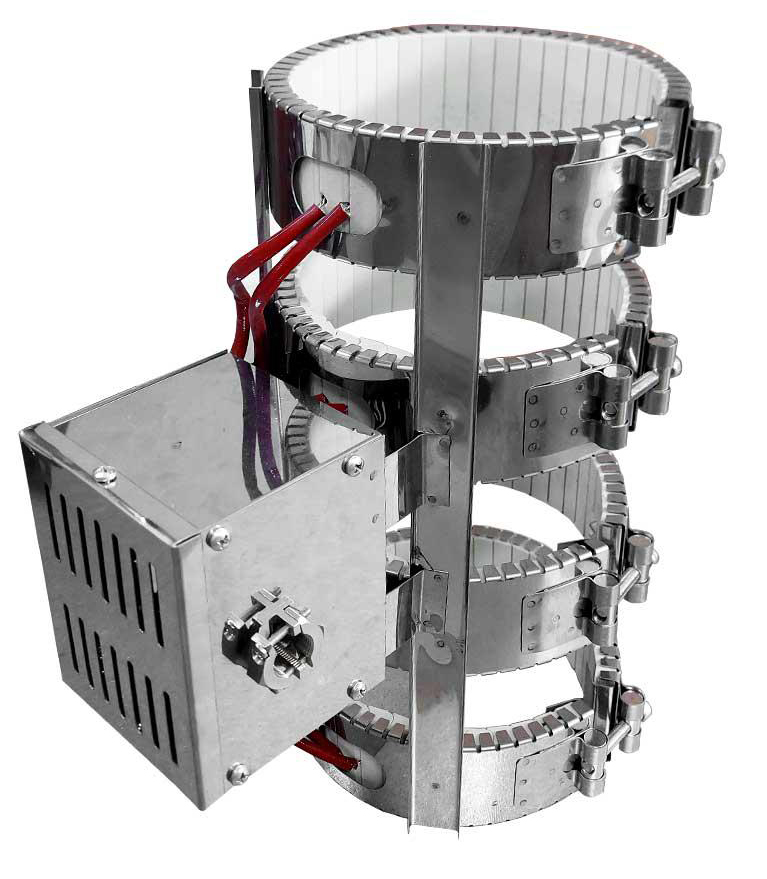

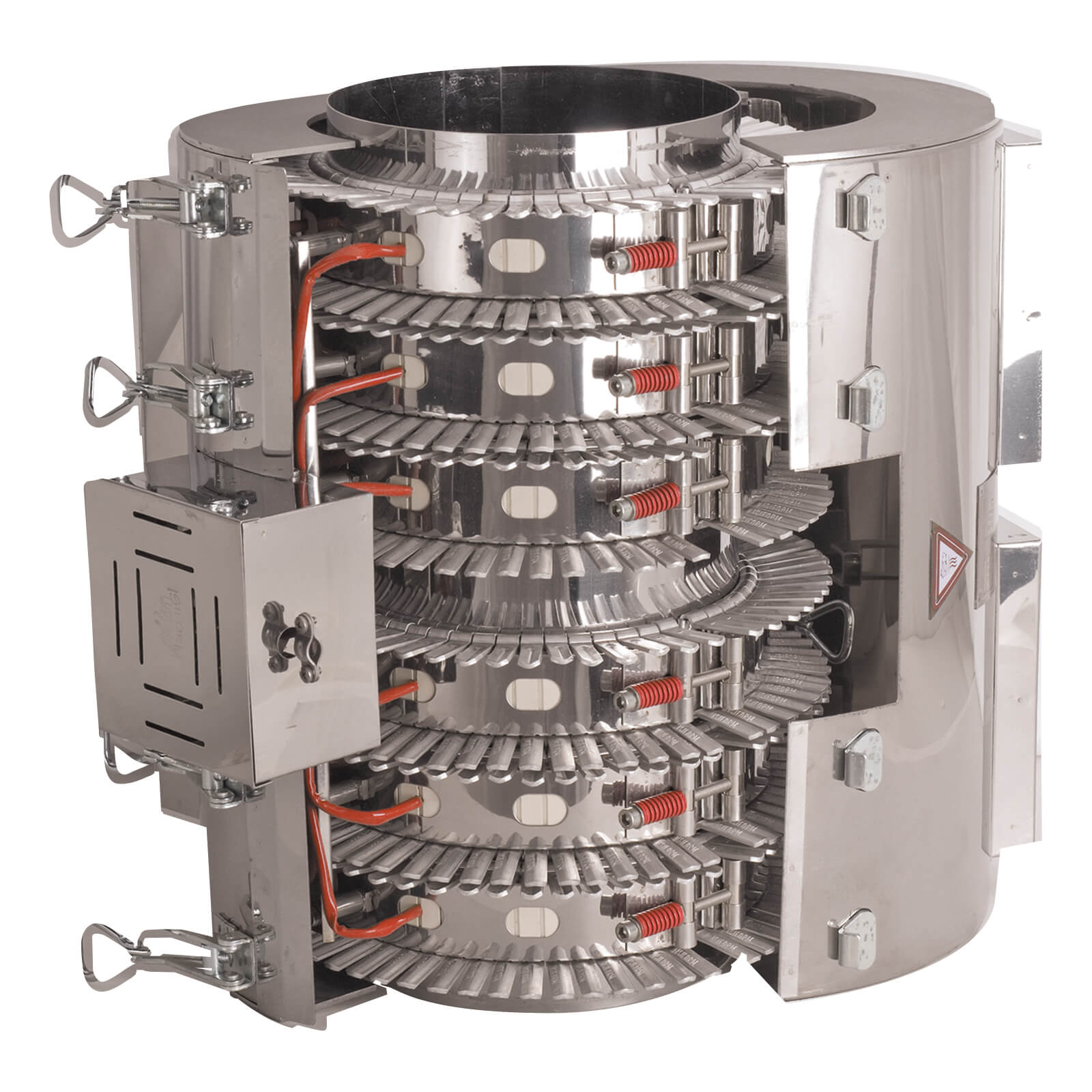

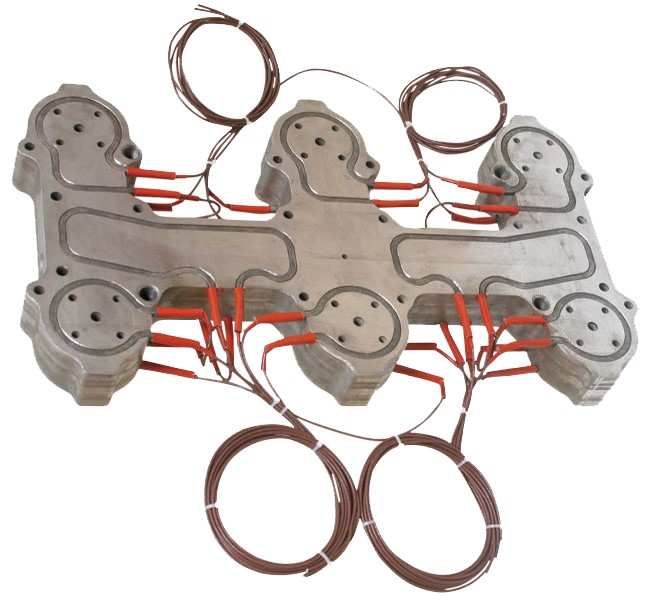

These heaters are manufactured by wrapping 60/15 - 80/20 1100ºC chrome-nickel wire on 800ºC high purity mica and coating it with stainless sheet, brass sheet or copper sheet. In this way, the thermal conductivity increases.

-In order to save heat and energy, 1260ºC imported ceramic fiber, which does not contain carcinogenic substances, is used.

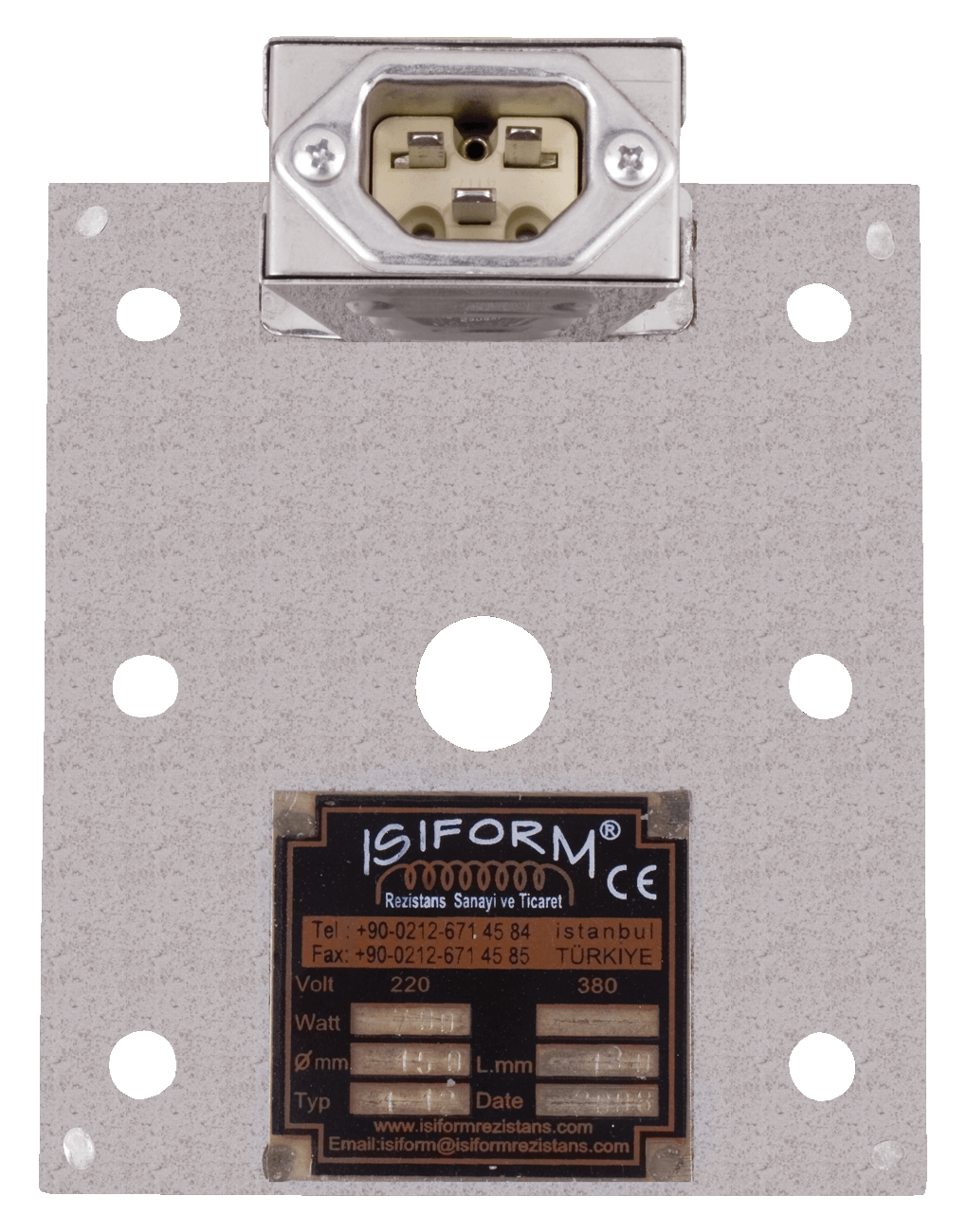

-Connections are made of static terminal blocks and iron plugs that are resistant to high temperatures and amperage.

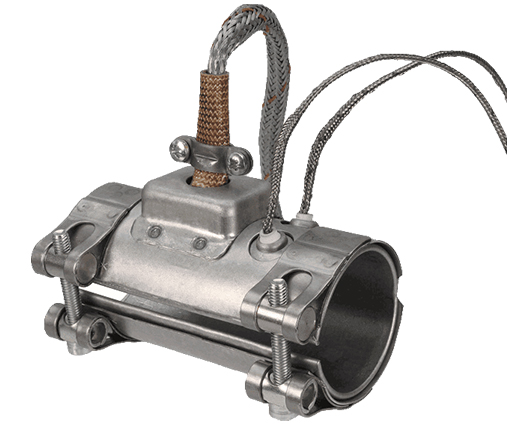

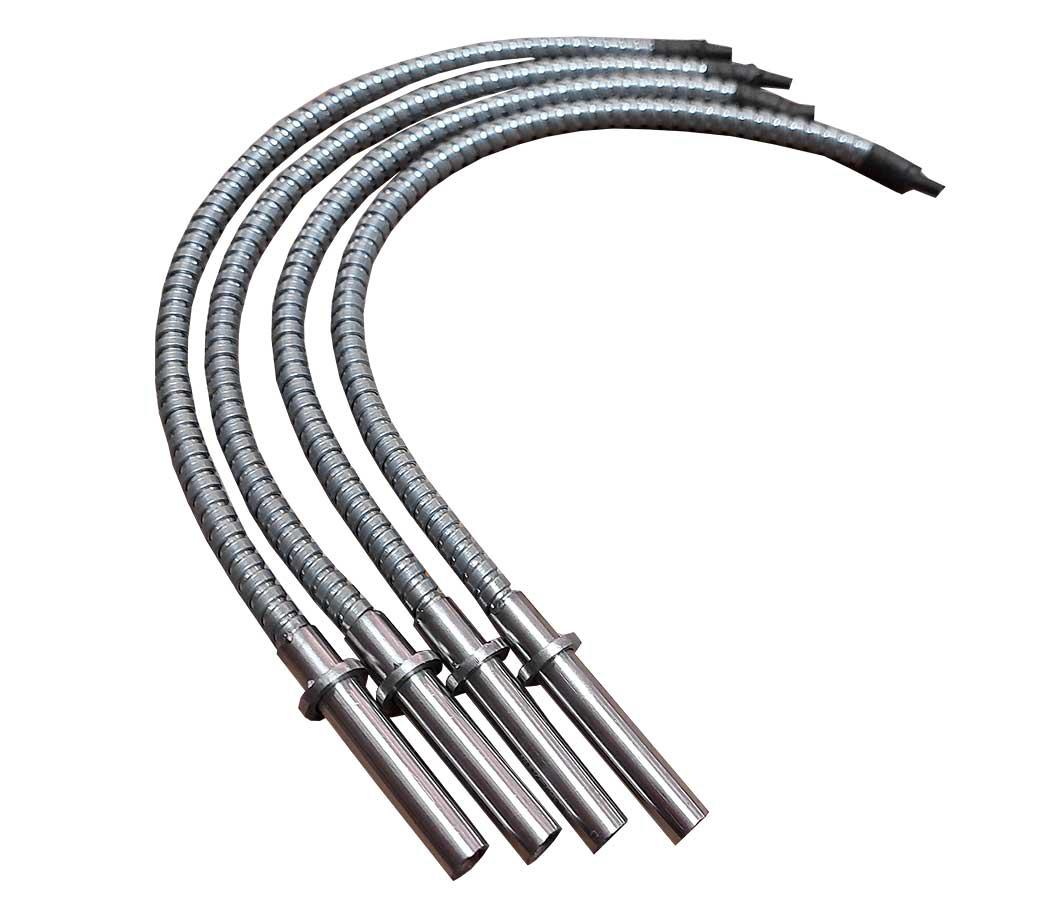

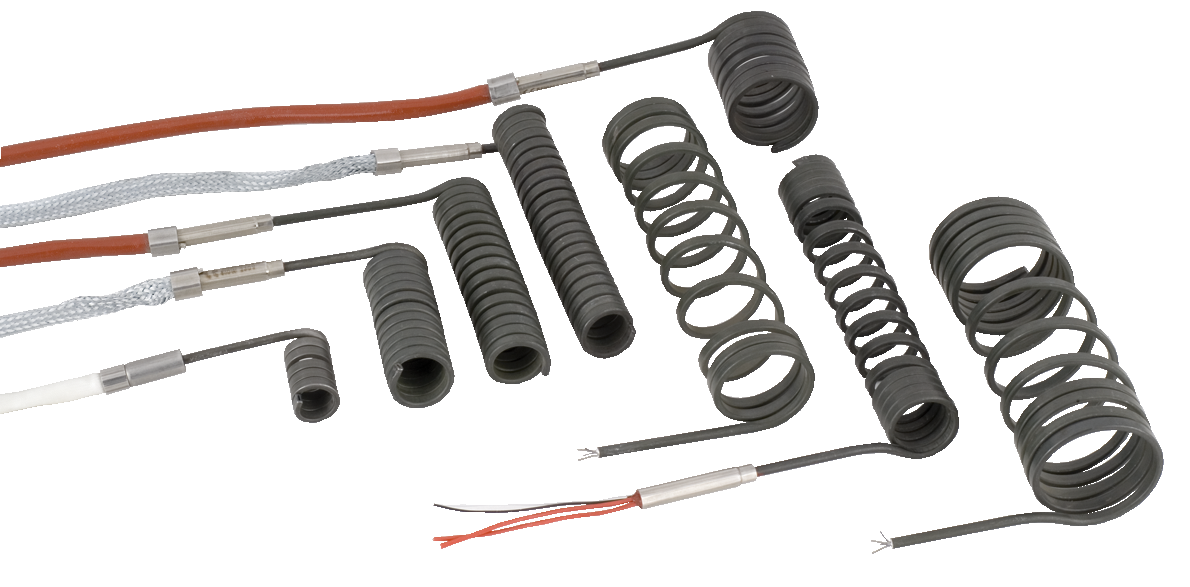

-For those with cable outlets, 400ºC imported multi-core nickel glass fiber cable and outer surface steel braided armored cable are used.

-These resistors according to their usage areas; They are mica type heaters made up to 3.5 watts per cm² in areas such as injection - blowing - bodinozes - melting etc.

-Resistors manufactured according to special orders in desired sizes and values, other than standards, provide energy savings of 15% to 40% depending on where they are used.

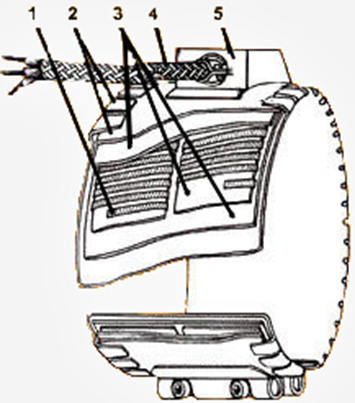

- Resistance wire (80/20,60/15)

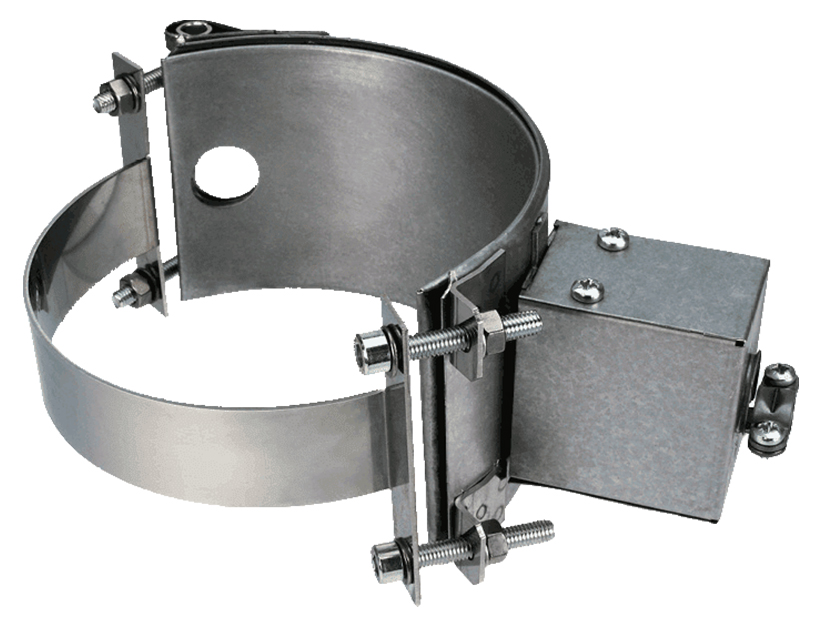

- Outer sheath (stainless steel sheet)

- 800ºC high purity mica

- Cable

- Energy junction box

Note:

Energy connections of mica insulated heaters can be produced in any desired form (plug, terminal, screw, cable).

Our heaters are manufactured in the desired diameter, length, volt and wattage.