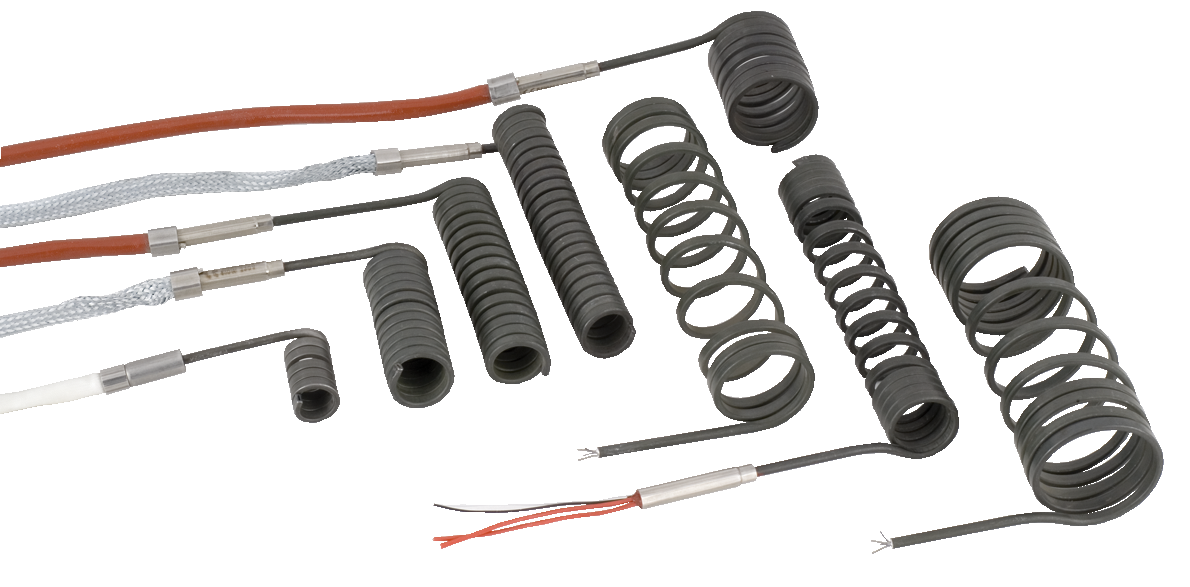

Ceramic Insulated Resistors

Ceramic Insulated Resistors Features

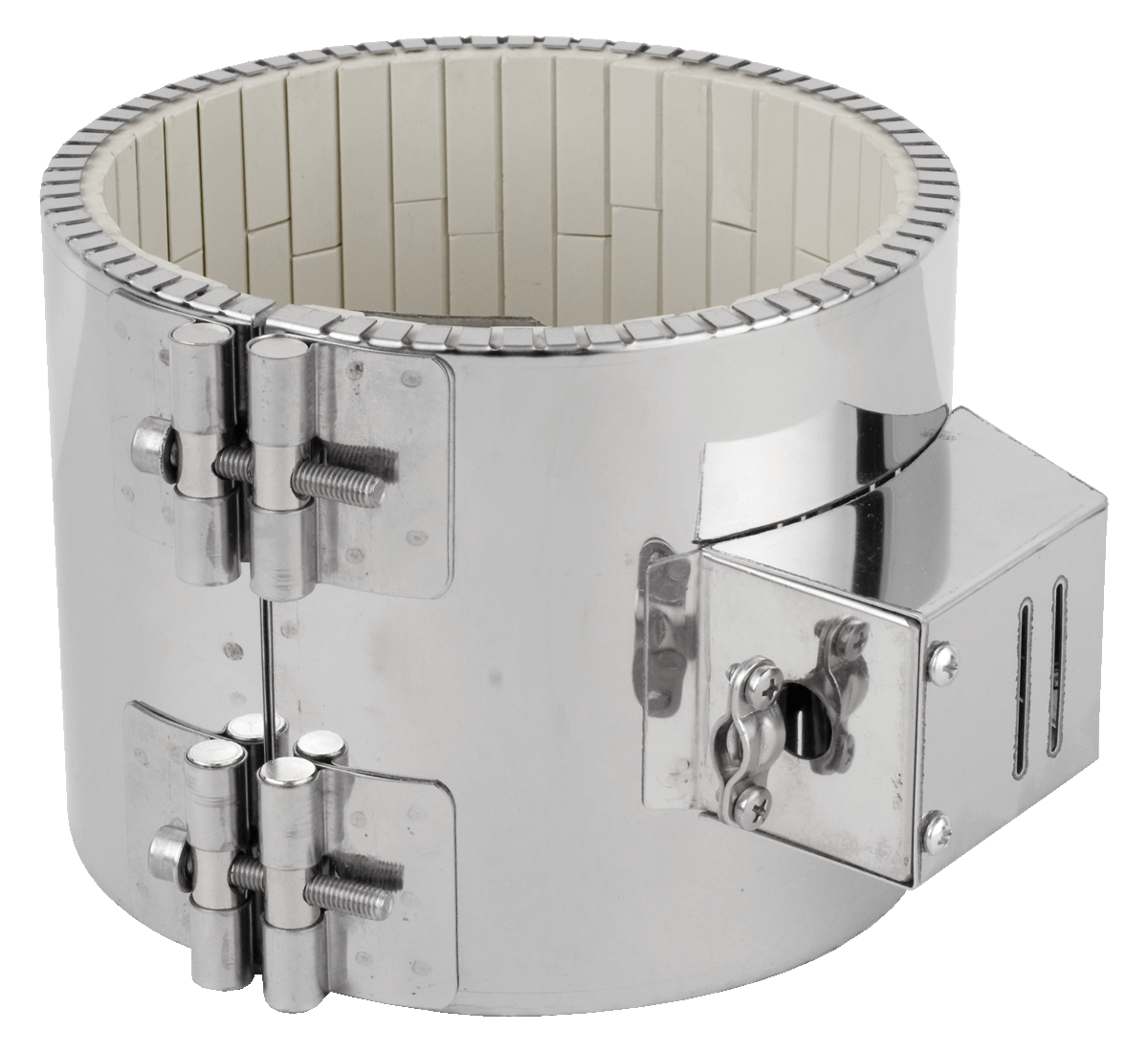

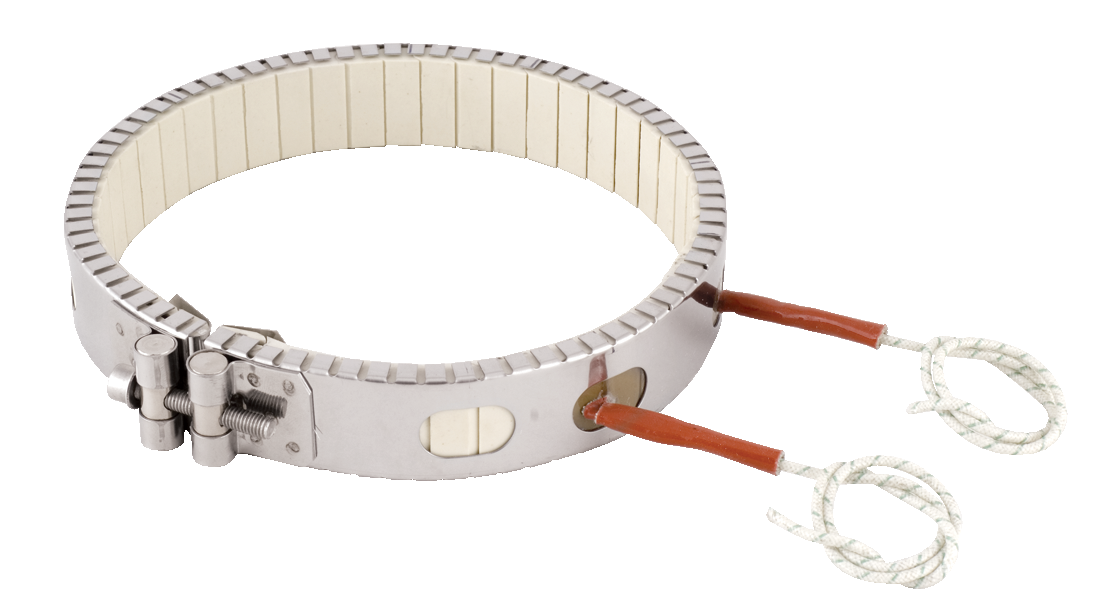

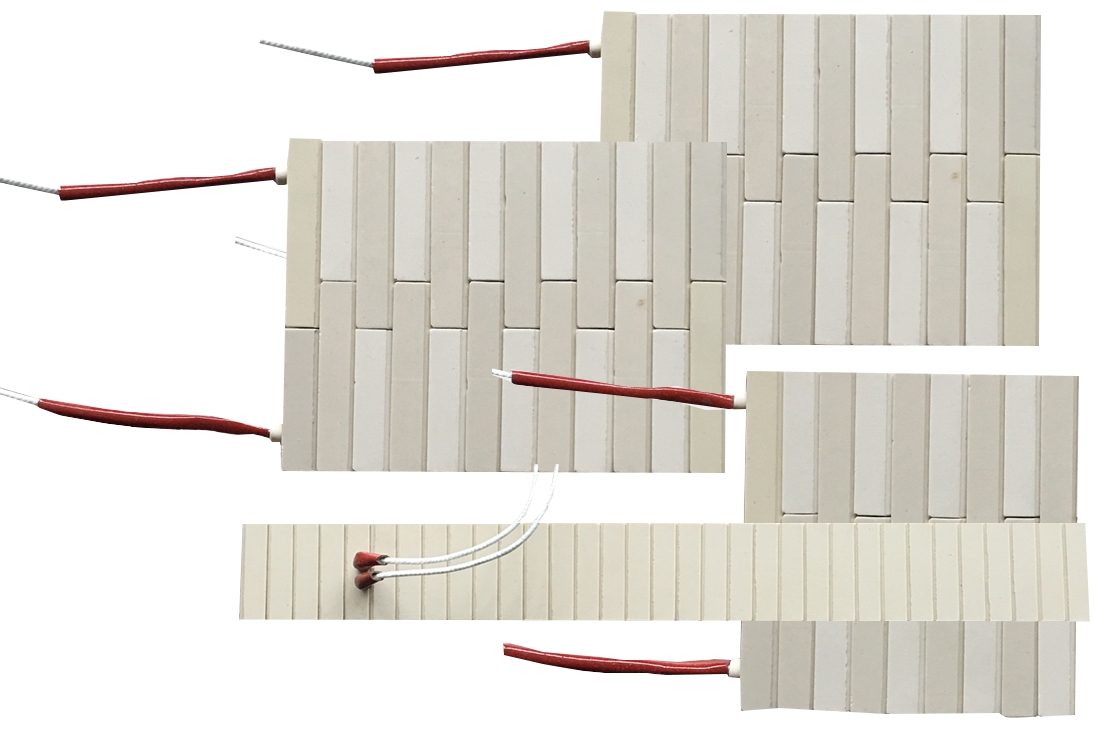

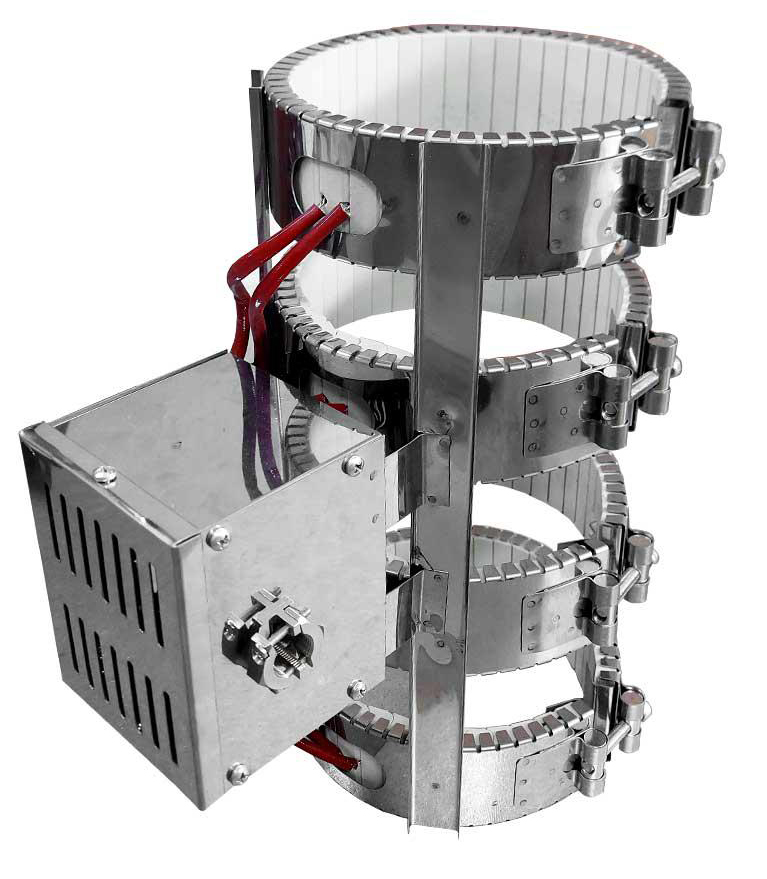

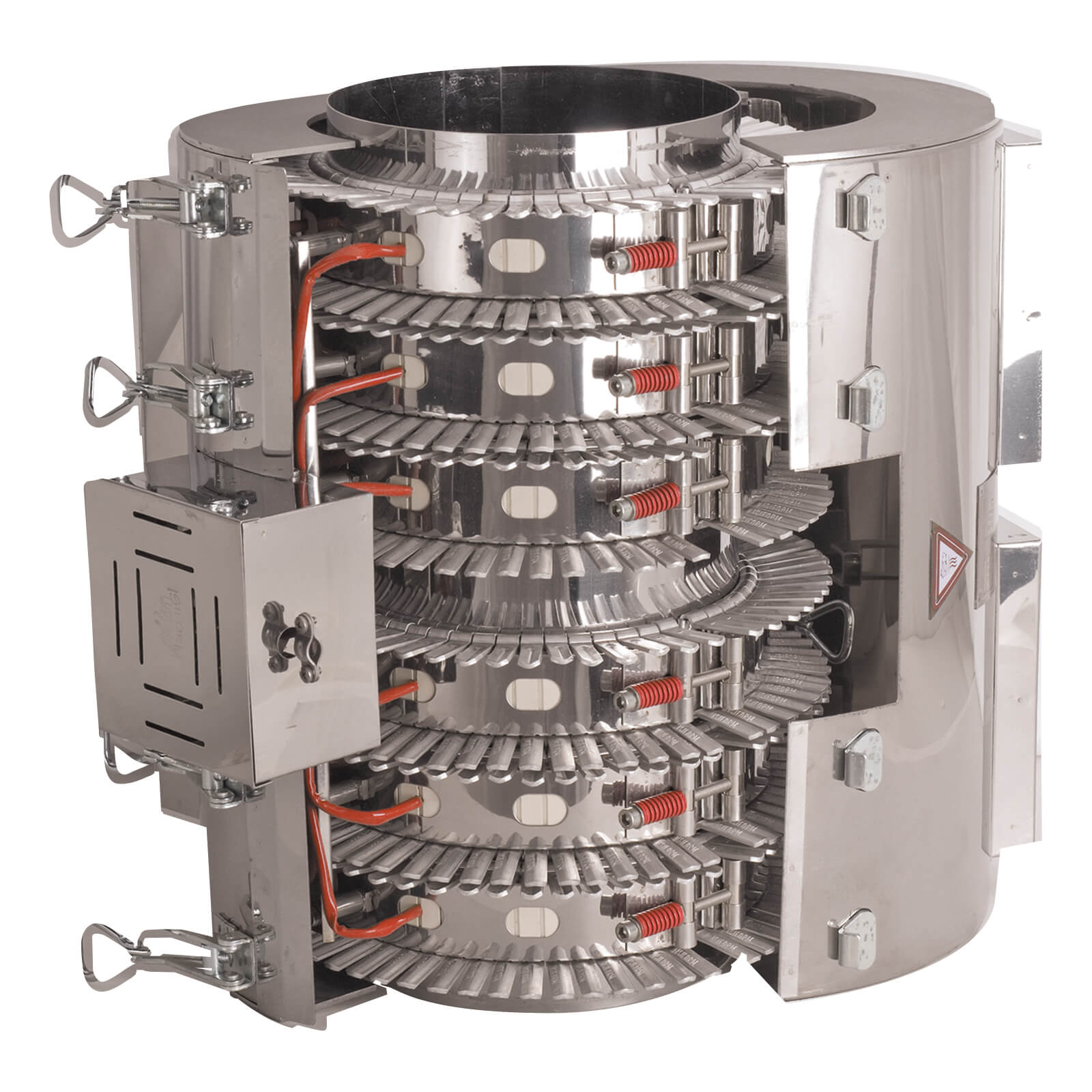

Ceramic insulated heaters are prepared by arranging 80/20 1100ºC chrome-nickel wire on special steatite belt stones and covered with stainless steel on the outside.

Thanks to ceramics with high heat permeability, a very long durability period, rapid and simultaneous dissipation of heat is achieved by placing the chrome-nickel spiral wire very well. It can be easily used in applications up to 650°C.

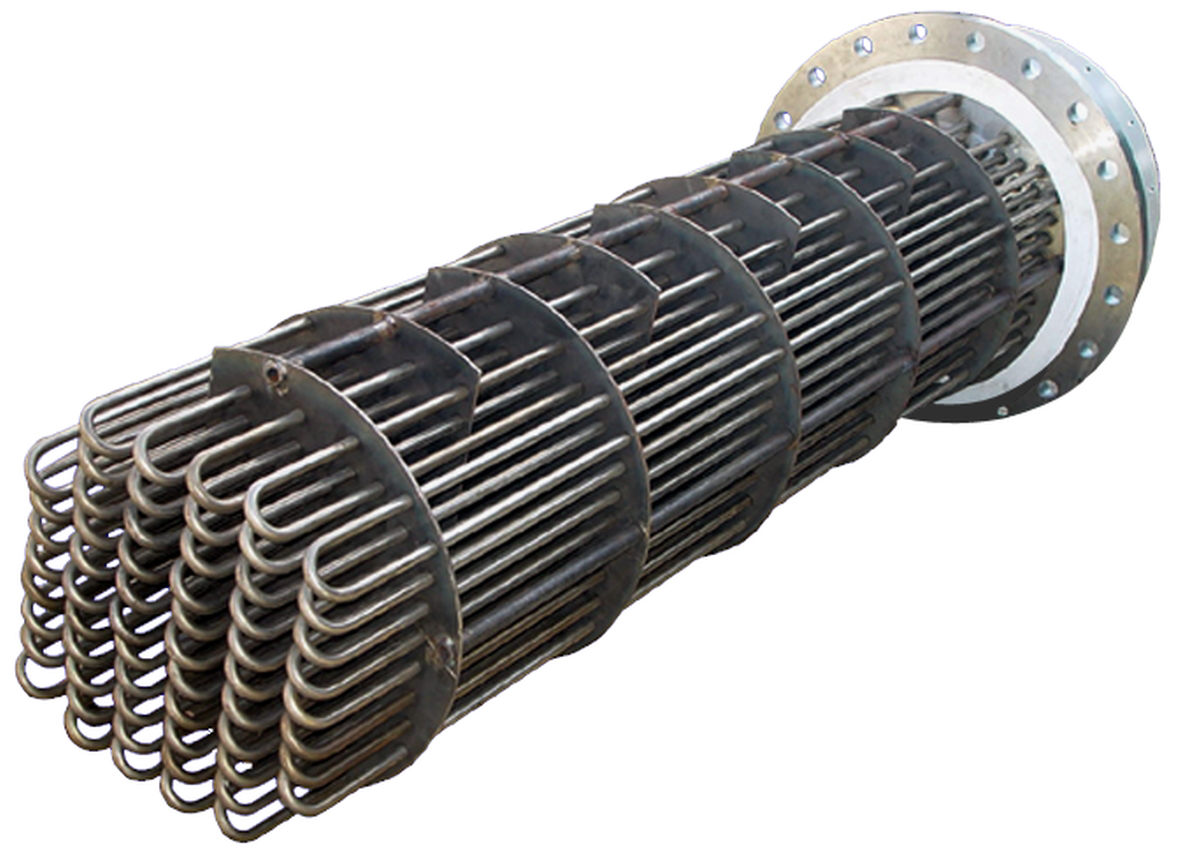

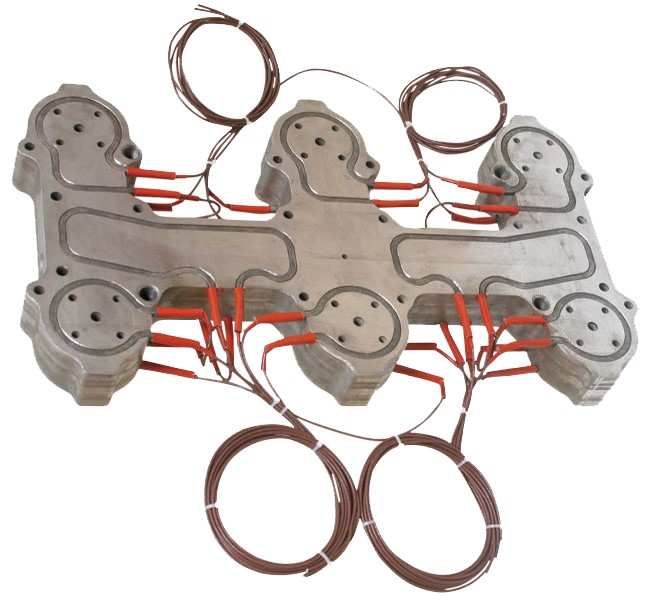

The main usage areas of ceramic insulated resistors are; These are extruder throat lines where the plastic raw material is shaped and molten flow is ensured. Apart from these, ceramic insulated resistors are widely used in externally tightened heating of pipelines, various tanks and special projects that require high heat and high power in minimal areas.

Thanks to the thermal insulation provided by ceramic fiber, energy savings of up to 25% to 45% are achieved.

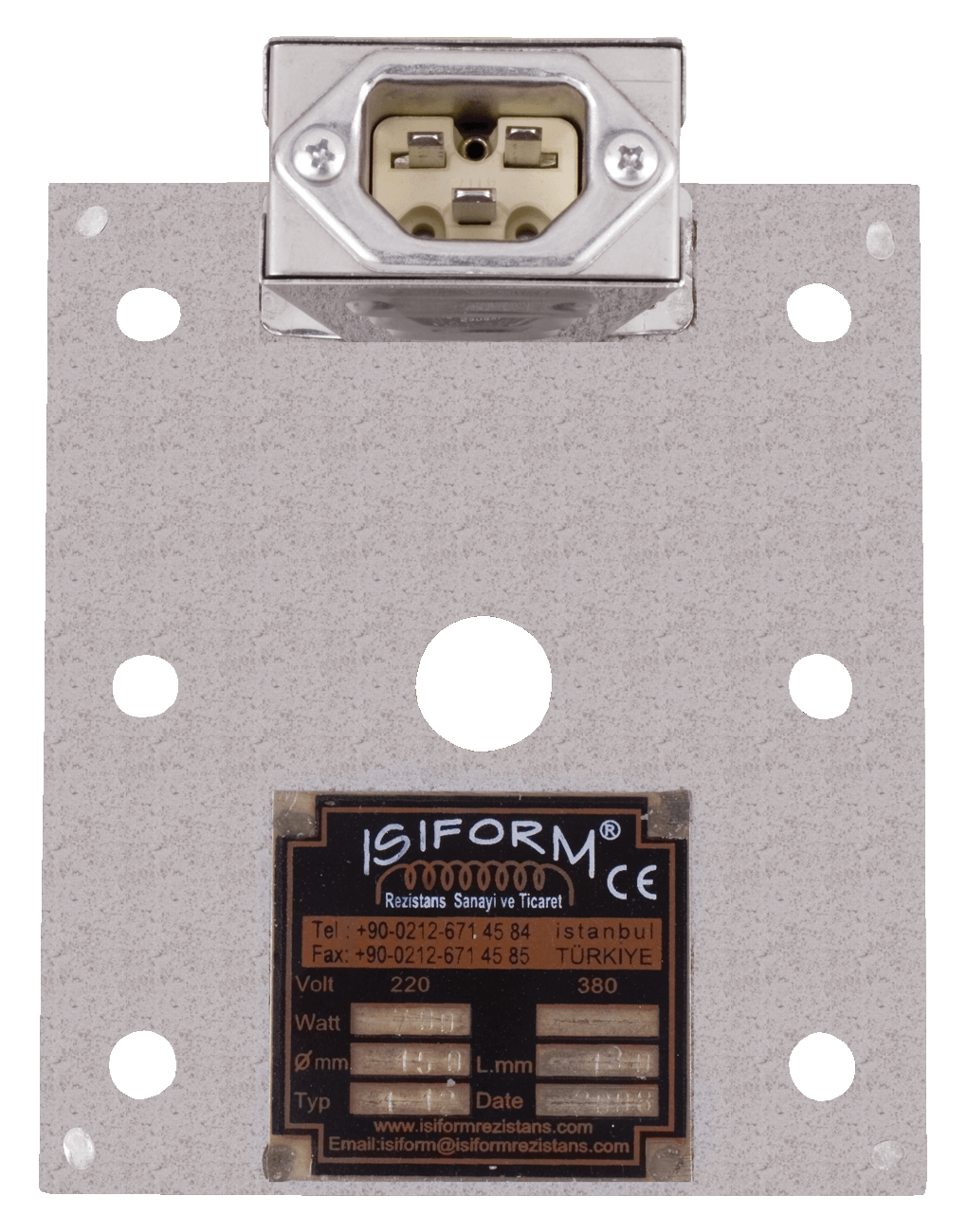

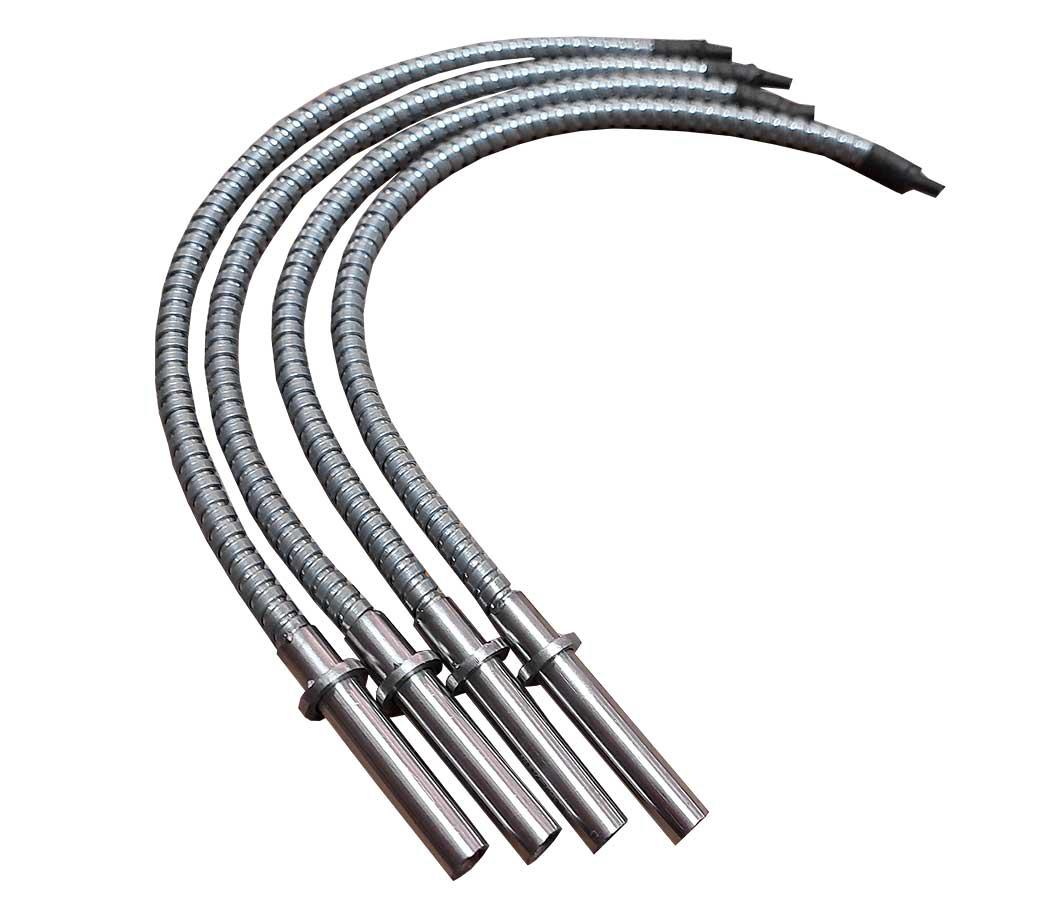

Connections are made with steatite terminal blocks and plugs that are resistant to high temperatures and amperage. Optionally, it can be assembled with 400ºC imported multi-core nickel glass fiber and steel armored cable.

Ceramic resistors can be loaded up to 7.5 watts per cm².

These heaters can be made in desired sizes and values.

Technical Specifications:

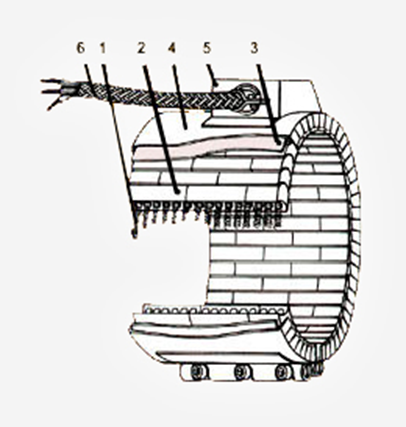

1- Resistance wire (80/20)

2- Ceramic stone (steatite)

3- Ceramic fiber

4- Outer sheath (stainless steel sheet)

5- Energy connection box

6- Cable

Note:

The energy connections of ceramic insulated heaters are produced in the desired shape (plug, terminal, screw, cable).

Our heaters are manufactured in the desired diameter, length, volt and wattage.