Manifold Resistors

Manifold Resistors Properties

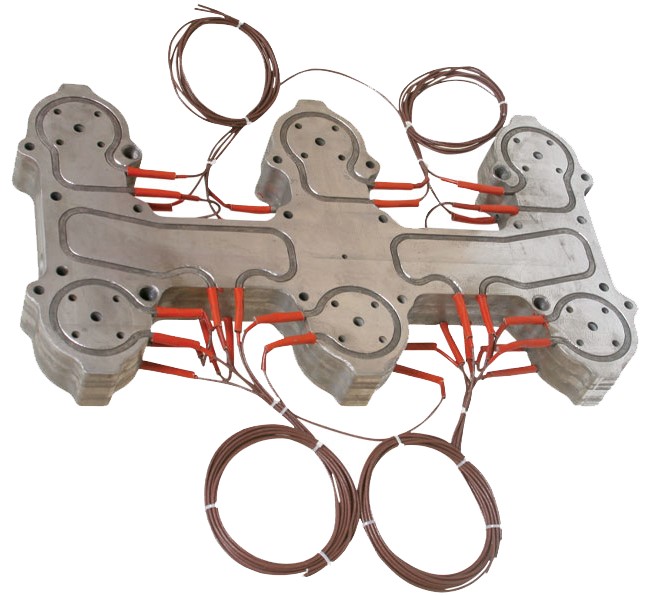

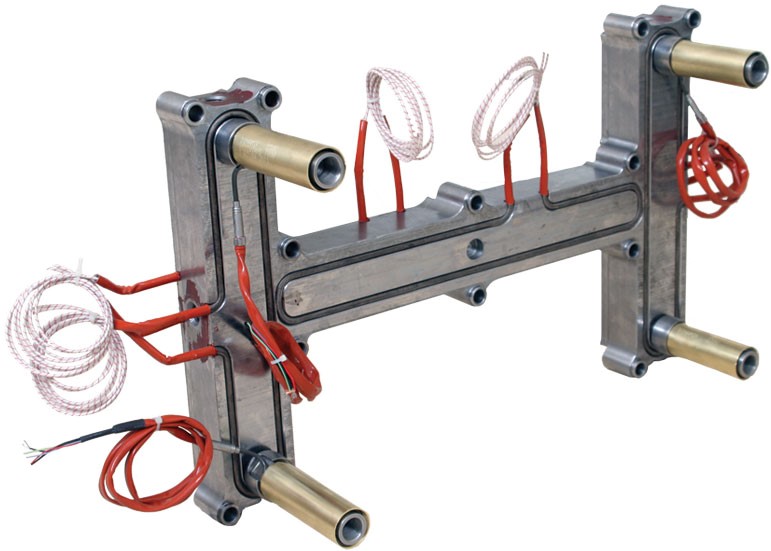

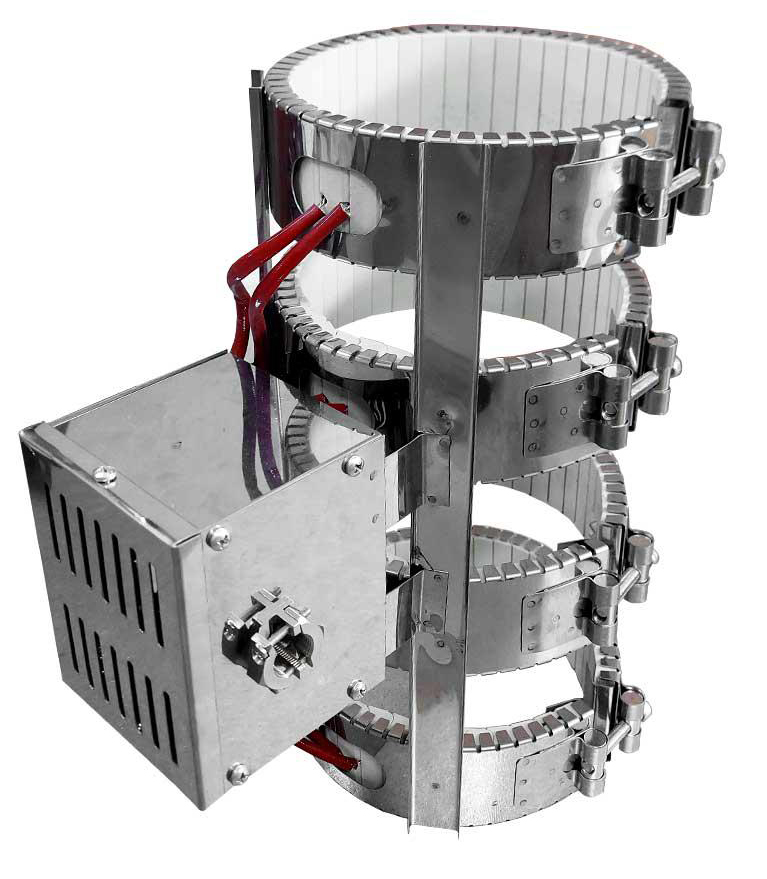

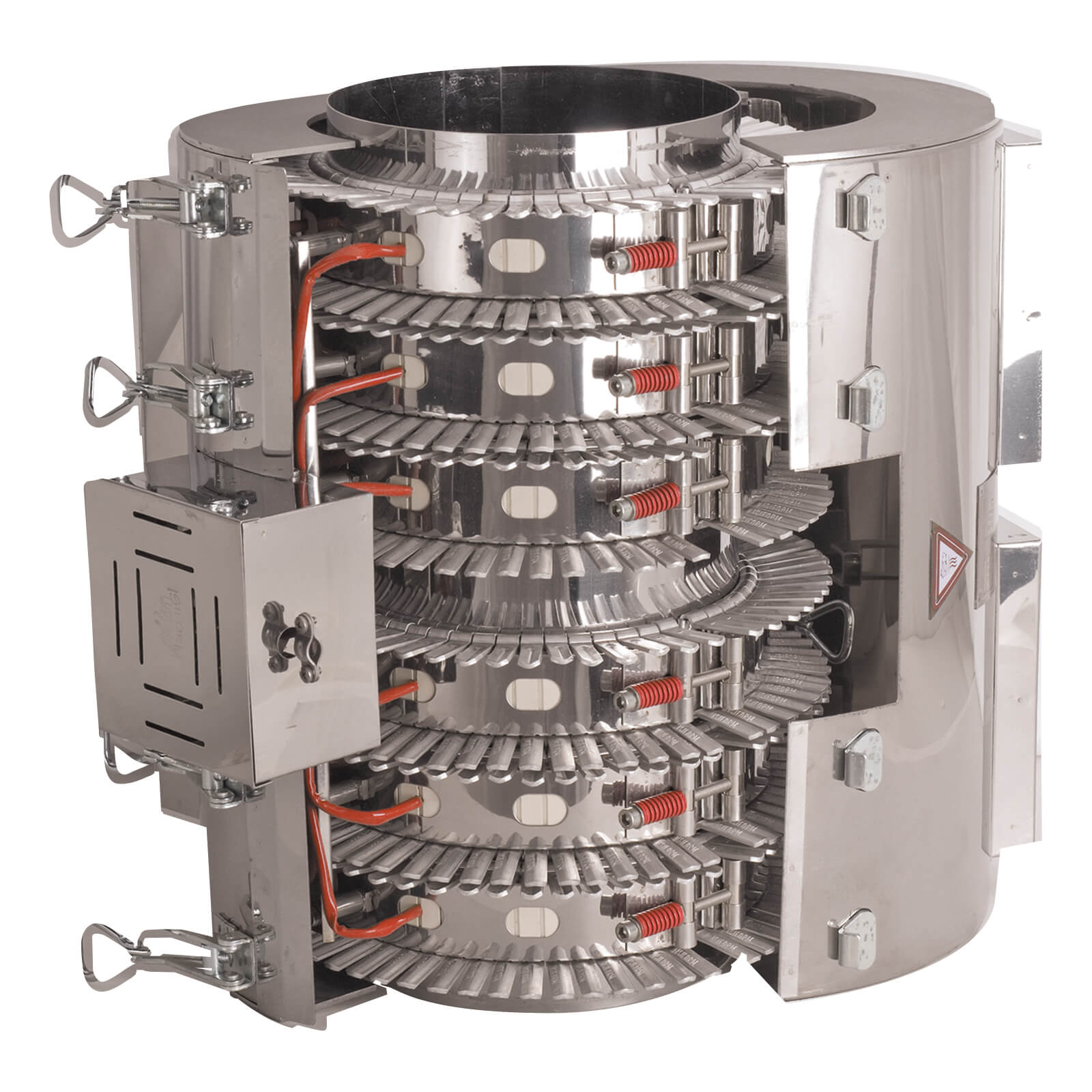

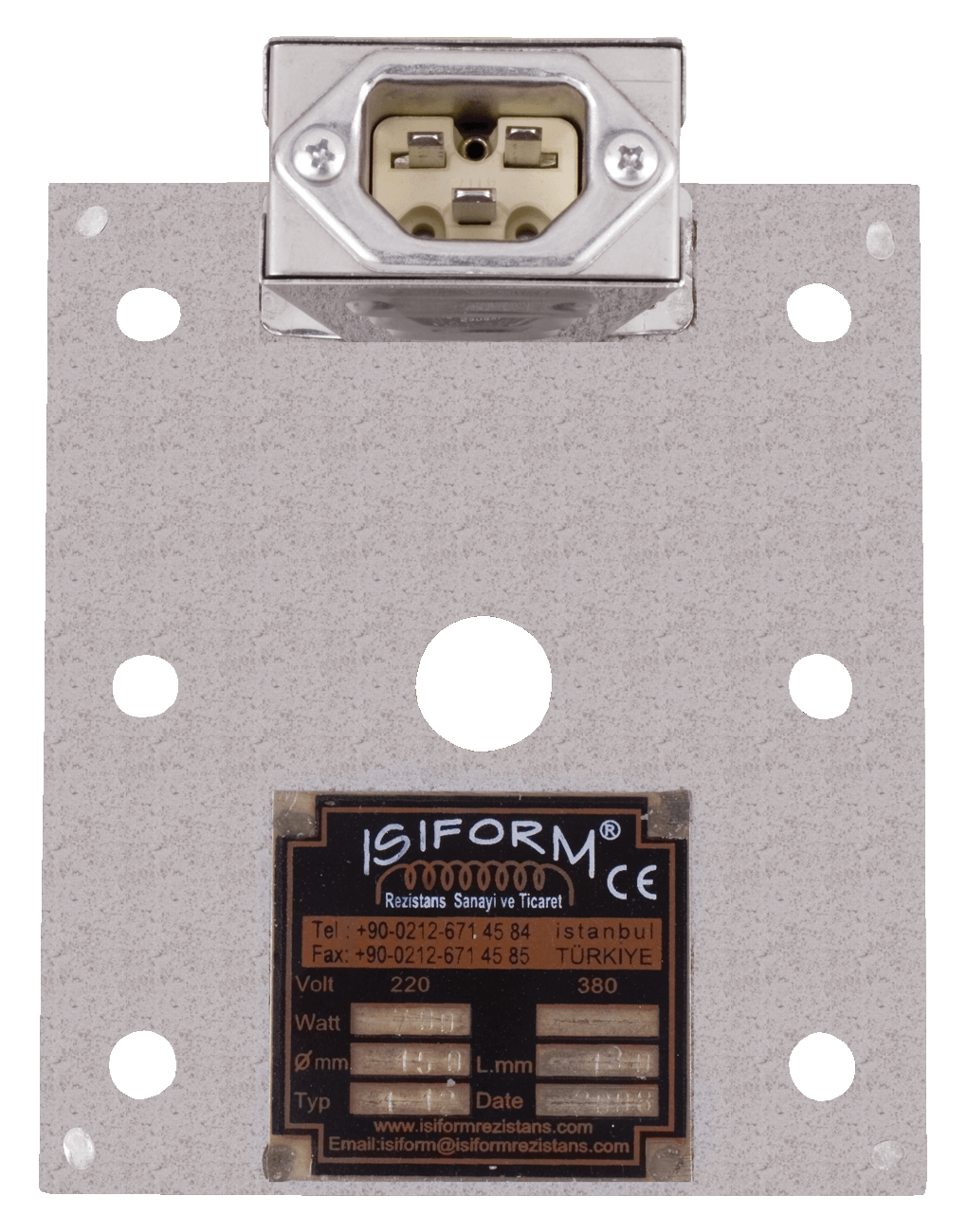

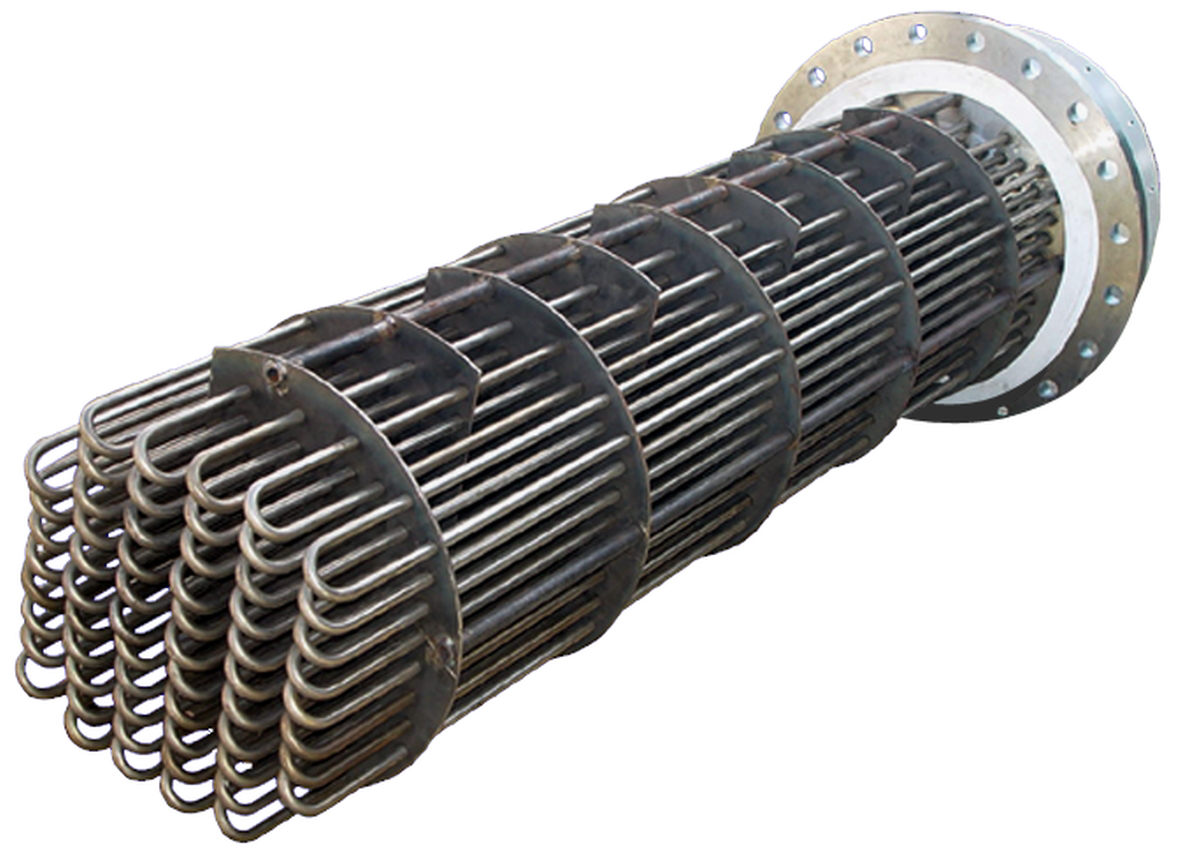

Manifold Heaters can be used in various applications depending on the reliability and versatility in their structure. For example, it is designed to be used in different hot runner systems in plastic injection nozzles. Manifold Heater models are of great importance to ensure the stabilization of the injection process of hot runner systems. Therefore, when choosing hot runner resistors, attention should be paid to operating temperatures and dimensions. Manifold resistors, which are produced using the latest technologies, also have the advantage of easy installation.

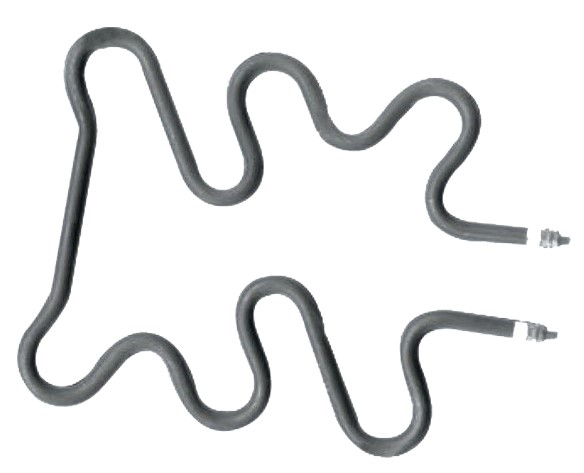

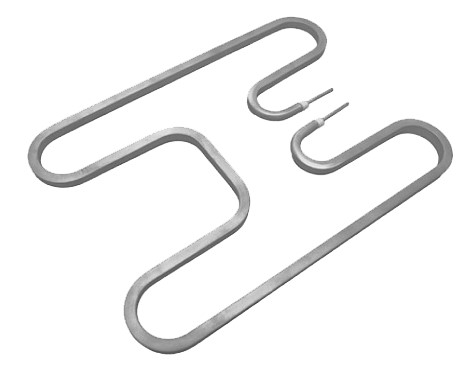

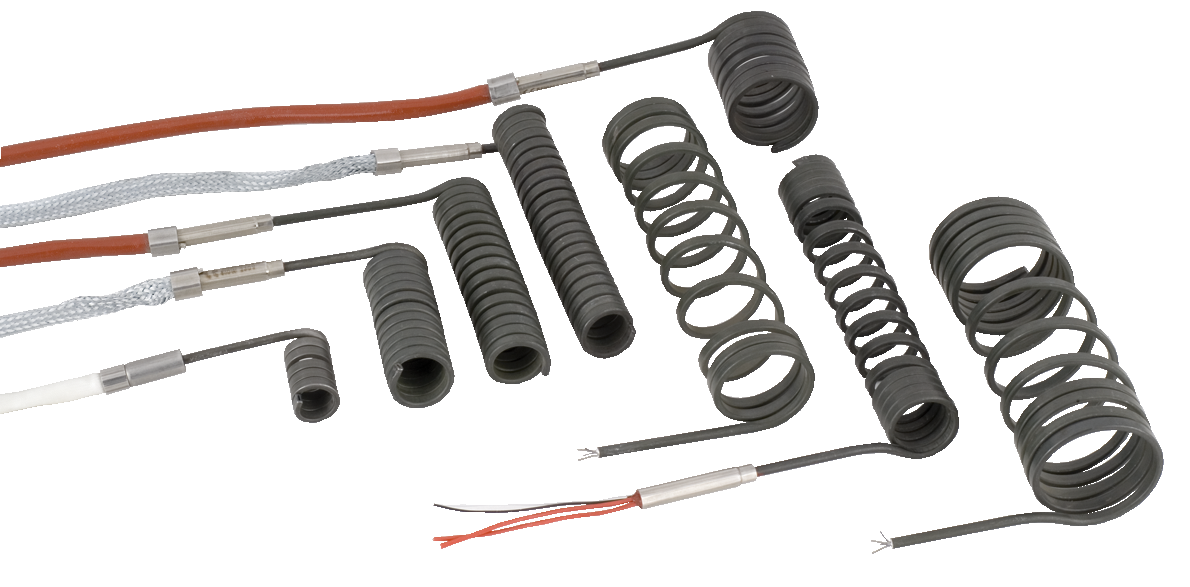

Manifold resistors are produced in two models and shaped according to molds.

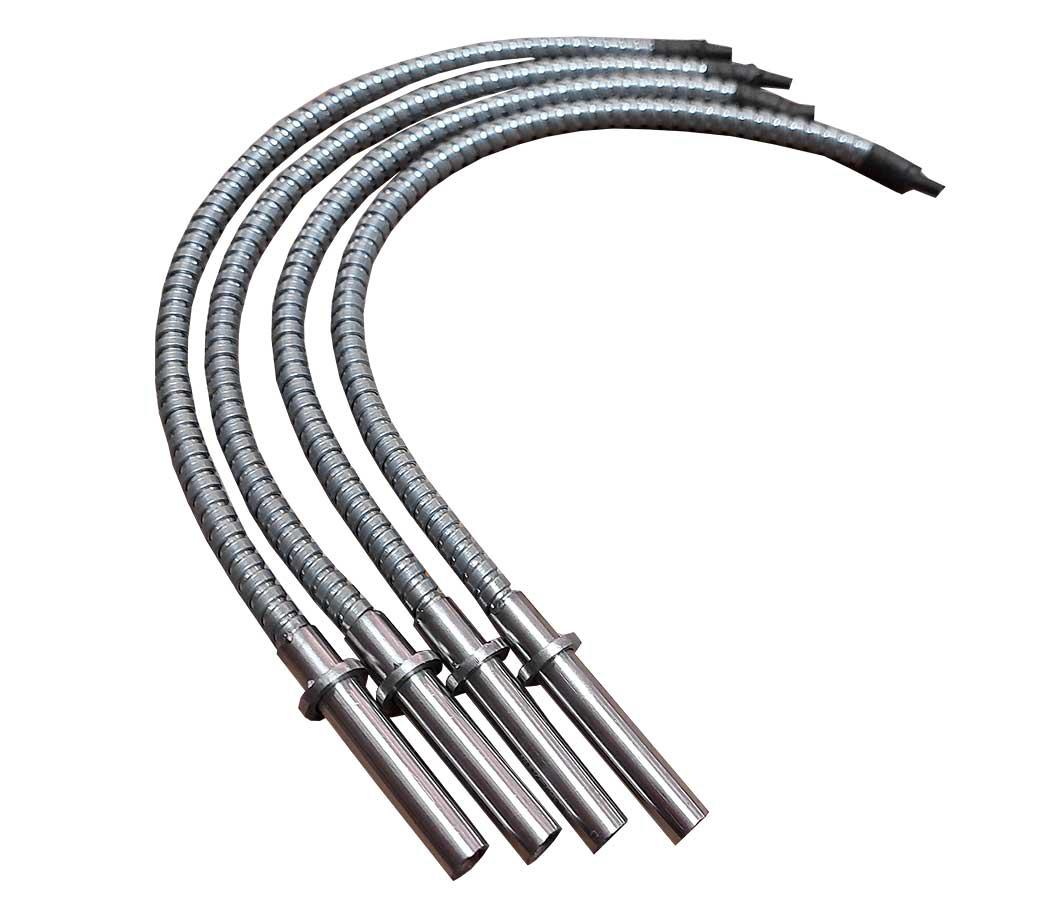

Since square section resistors have more surface contact, they reach the required temperature in a short time. The life of the resistor is extended and electricity consumption is reduced.

Round cross-section resistors reach the desired temperature late because they have less surface contact. Heat loss occurs. Electricity consumption increases. It is manufactured in this model according to the need.

Manifold Heaters can be easily produced in different winding types and different output directions according to customer demands and requests. Manifold resistor models, which are extremely comfortable and easy to assemble, are produced with raw materials that have high strength properties.