Coated Bathroom Resistance

What is Coated Bathroom Resistance?

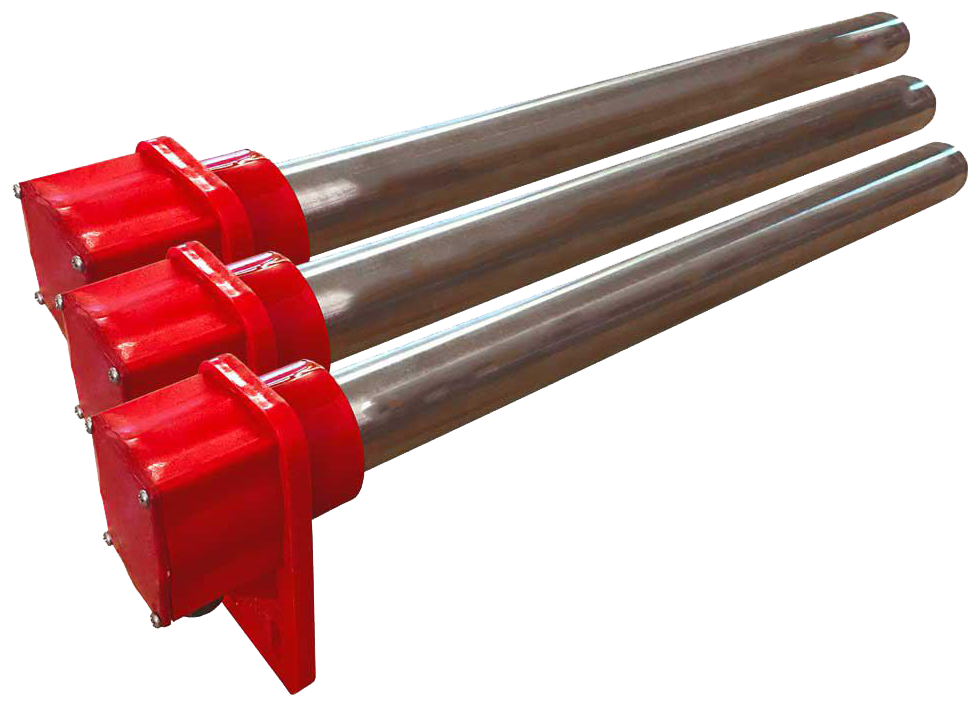

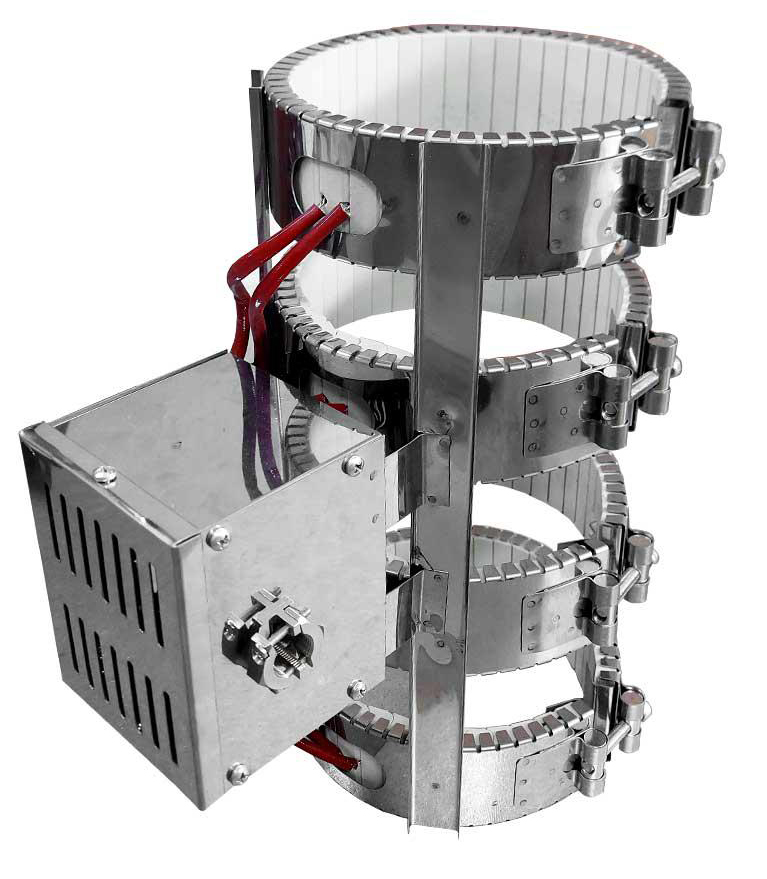

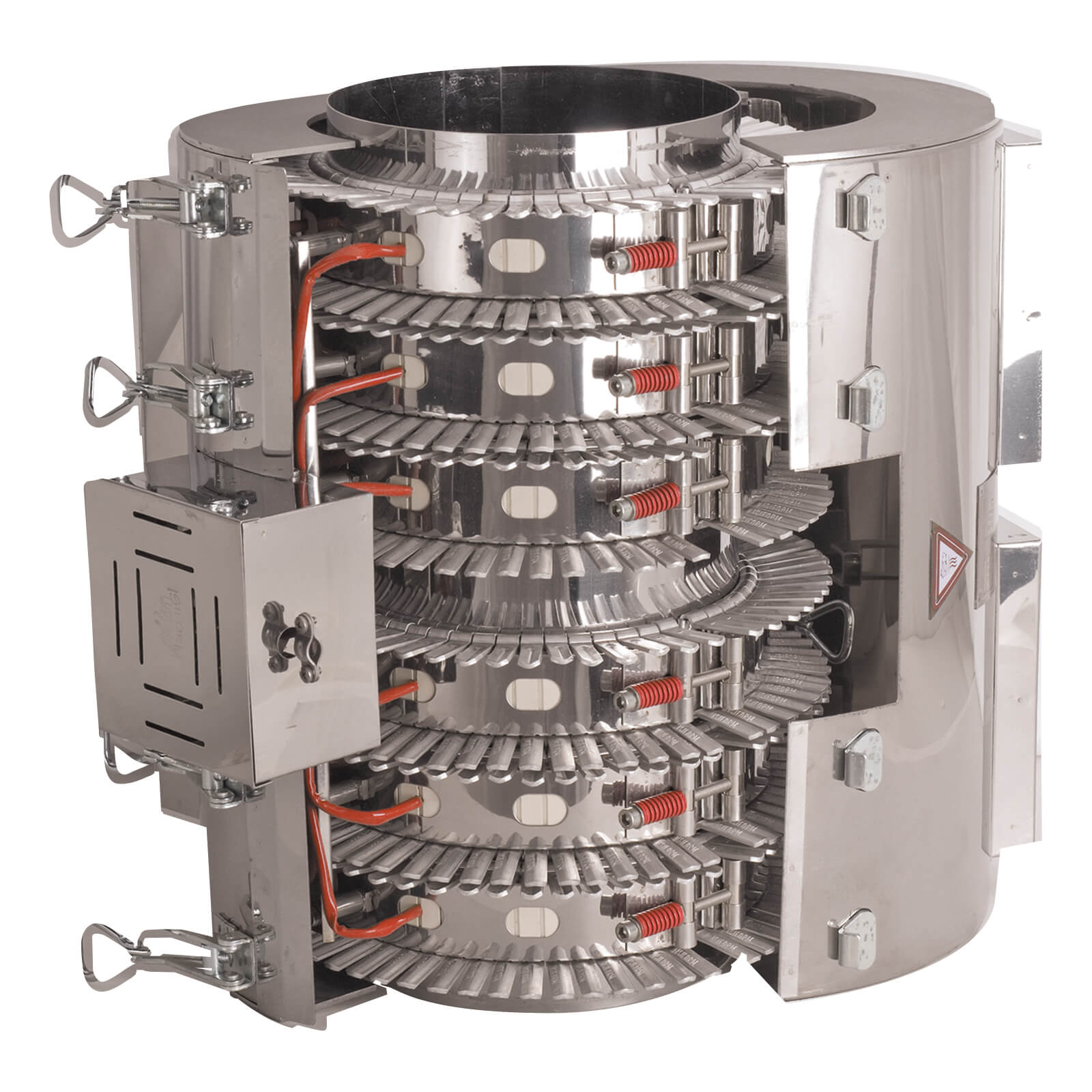

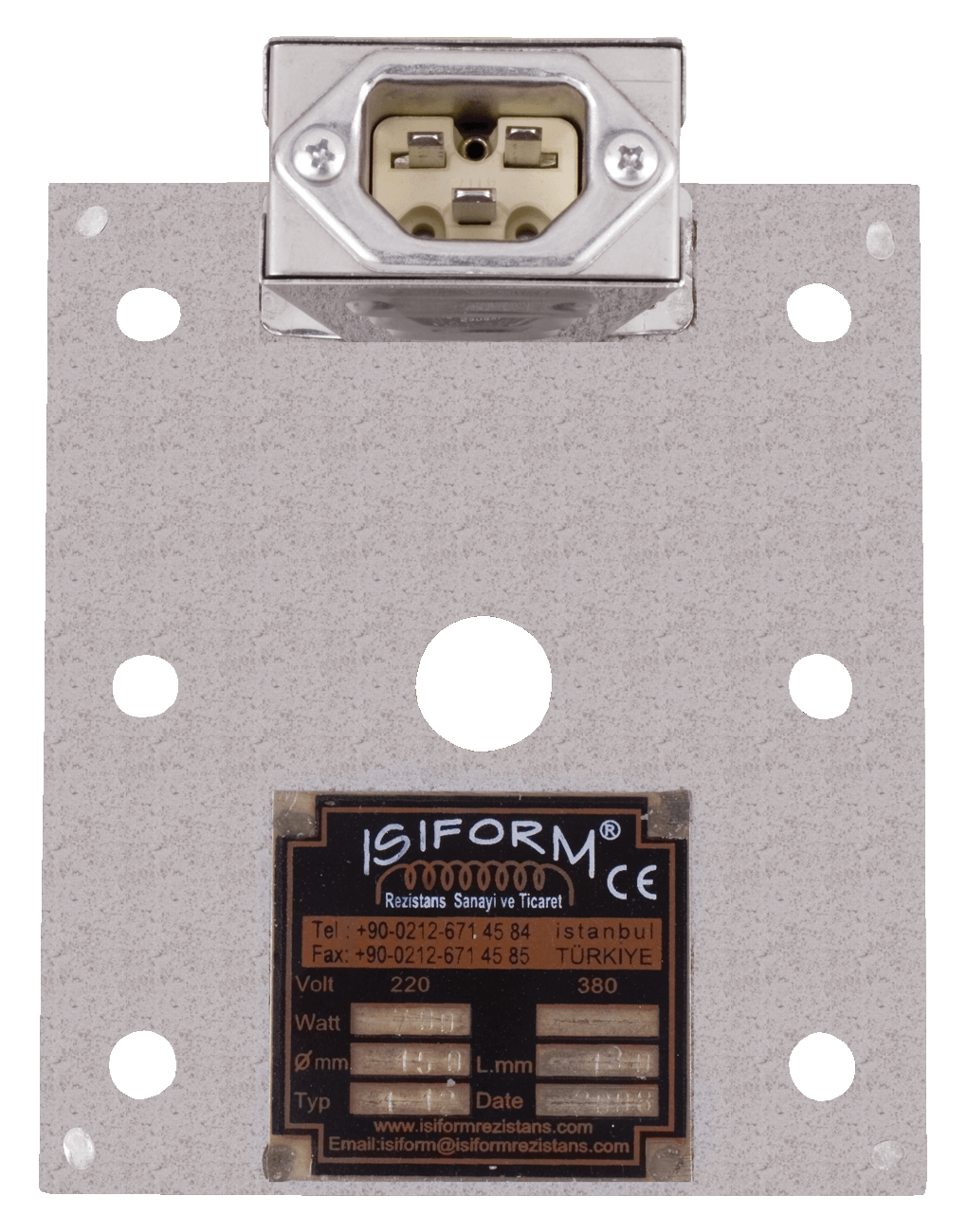

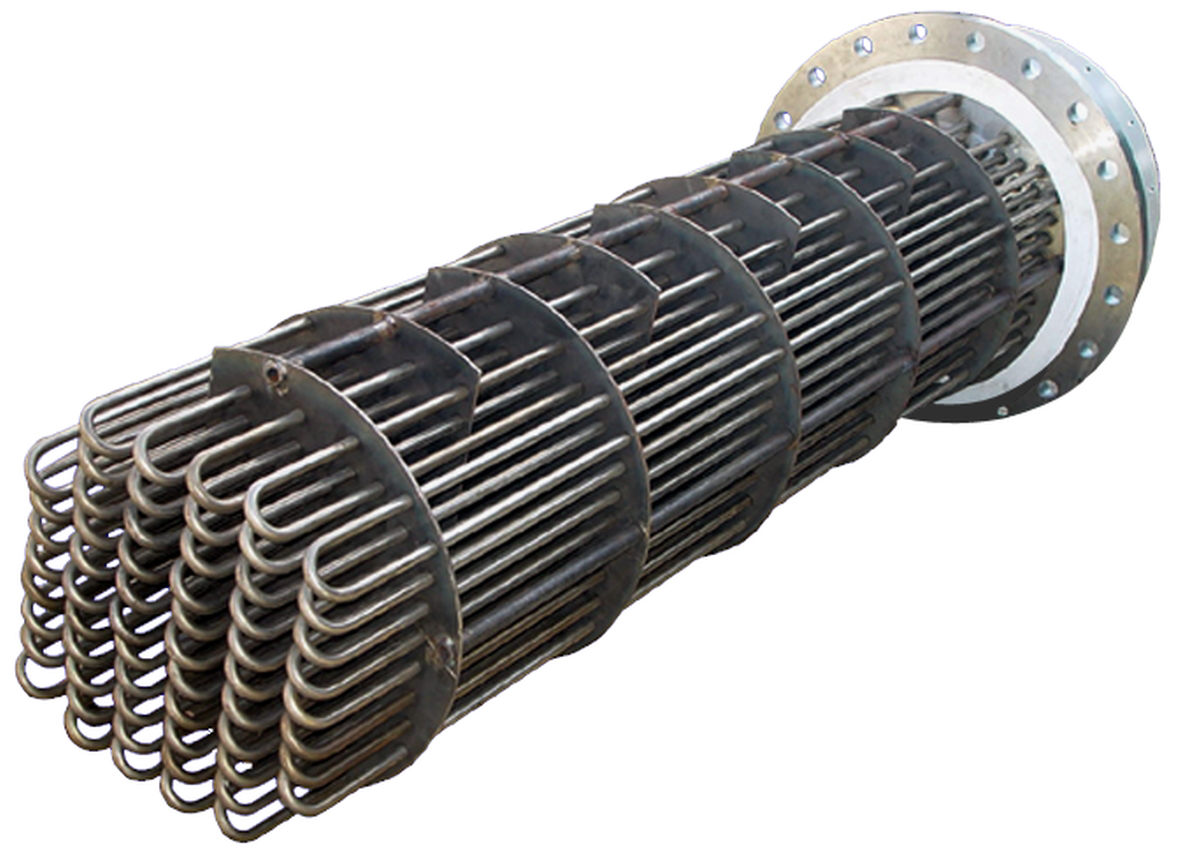

Plating bath resistance is a heating element used during metal plating processes. Metal plating is the process of adding another layer of metal or alloy to the surface of a metal object. Plating baths are located in tanks or baths used to perform this process. Plating bath resistors are used to heat the plating solution or electrolytic bath in these tanks.

The main function of plating bath resistors is to provide the temperature required for the coating material to melt or chemical reactions to occur during the plating process. These resistors are usually mounted on the walls or bottom of the tank and maintain the liquid or bath within the tank at a certain temperature.

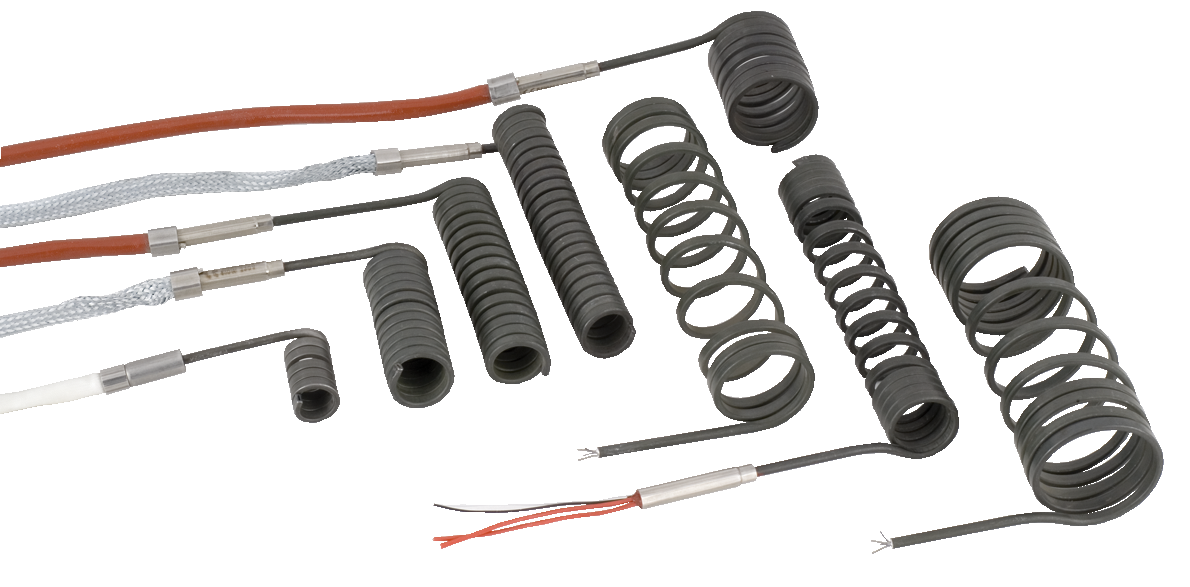

Plating processes are used in a variety of industrial applications, for example to create protective coatings or decorative coatings of metal parts. Plating bath resistors are important due to their ability to provide continuous and precise temperature control in such processes.

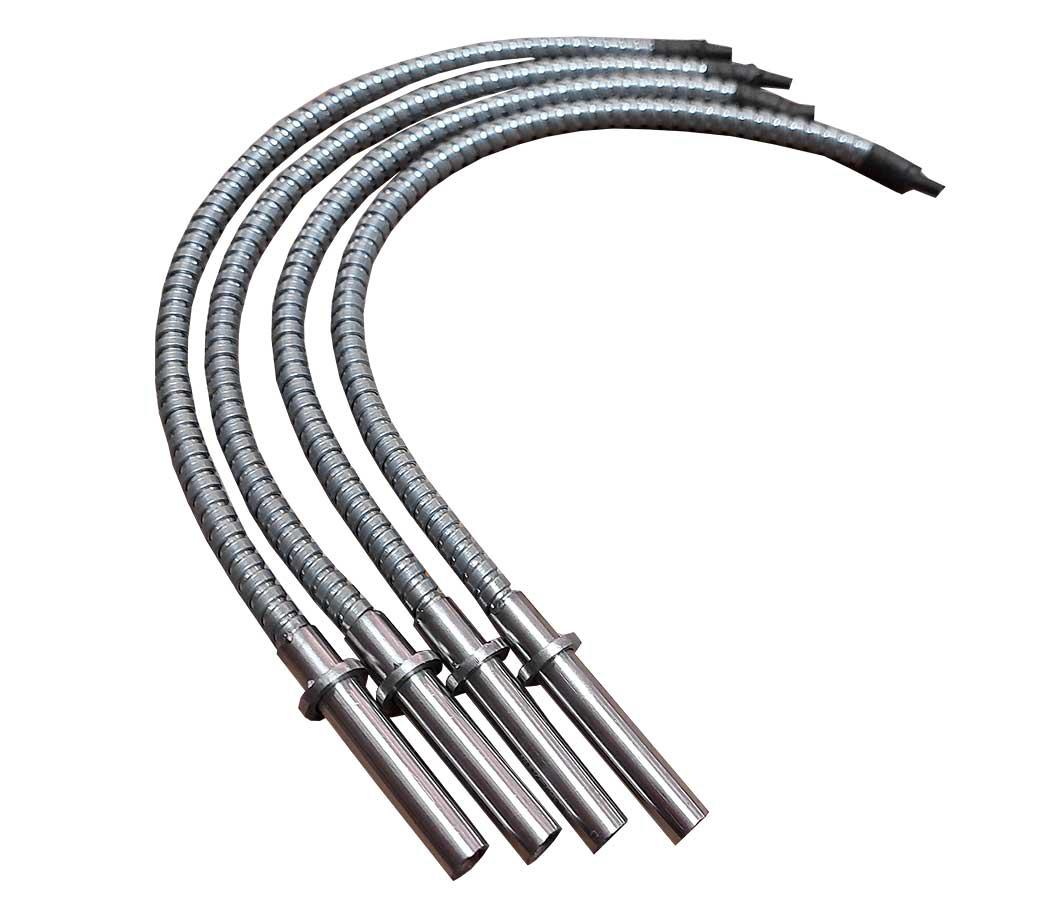

This type of resistors are made of Chrome, Teflon, Copper, Brass, Iron, Quartz, Titanium and Glass in their bodies to prevent rapid wear and deterioration due to chemical interaction. It has increased durability and is used in all chemical materials. It is manufactured in the desired dimensions by passing a teflon hose over the stainless pipe.